Workshop 07: Non-isothermal reactor design

Lecture notes for chemical reaction engineering

Solutions to these problems are uploaded at Workshop 7 solutions

Try following problems from Fogler 5e P 11-5, P 11-6, P 12-6, P 12-21

We will go through some of these problems in the workshop.

P 11-5

The elementary, irreversible gas-phase reaction

is carried out adiabatically in a PFR packed with a catalyst. Pure A enters the reactor at a volumetric flow rate of 20 dm3/s, at a pressure of 10 atm, and a temperature of 450 K.

Additional information:

; ;

; ;

All heats of formation are referenced to 273 K.

Plot and then analyze the conversion and temperature down the plug-flow reactor until an 80% conversion (if possible) is reached. (The maximum catalyst weight that can be packed into the PFR is 50 kg.) Assume that .

Vary the inlet temperature and describe what you find.

Plot the heat that must be removed along the reactor ( Q vs. V) to maintain isothermal operation.

Now take the pressure drop into account in the PBR with . The reactor can be packed with one of two particle sizes. Choose one.

- Plot and then analyze the temperature, conversion, and pressure along the length of the reactor. Vary the parameters and to learn the ranges of values in which they dramatically affect the conversion.

P 11-6

The irreversible endothermic vapor-phase reaction follows an elementary rate law

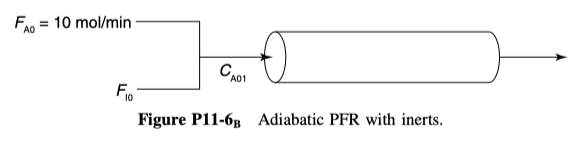

and is carried out adiabatically in a 500-dm3 PFR. Species A is fed to the reactor at a rate of 10 mol/min and a pressure of 2 atm. An inert stream is also fed to the reactor at 2 atm, as shown in Figure P11-6 B . The entrance temperature of both streams is 1100 K.

Additional information:

(T in degrees Kelvin);

; ; ;

First derive an expression for as a function of and .

Sketch the conversion and temperature profiles for the case when no inerts are present. Using a dashed line, sketch the profiles when a moderate amount of inerts are added. Using a dotted line, sketch the profiles when a large amount of inerts are added. Qualitative sketches are fine. Describe the similarities and differences between the curves.

Sketch or plot and then analyze the exit conversion as a function of . Is there a ratio of the entering molar flow rates of inerts (I) to A (i.e., at which the conversion is at a maximum? Explain why there “is” or “is not” a maximum.

What would change in parts (b) and (c) if reactions were exothermic and reversible with and at 1100 K?

Sketch or plot FB for parts (c) and (d), and describe what you find.

Plot the heat that must be removed along the reactor ( Q vs. V) to maintain isothermal operation for pure A fed and an exothermic reaction.

P 12-6

The endothermic liquid-phase elementary reaction

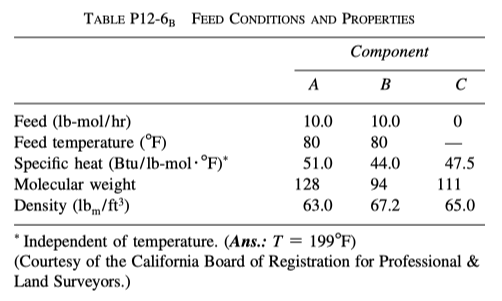

proceeds, substantially, to completion in a single steam-jacketed, continuous-stirred reactor (Table P12-6 B ). From the following data, calculate the steady-state reactor temperature:

Reactor volume: 125 gal;

Steam jacket area: 10 ft2

Jacket steam: 150 psig (365.9 F saturation temperature)

Overall heat-transfer coefficient of jacket, U: 150

Agitator shaft horsepower: 25 hp

Heat of reaction, Btu/lb-mol of A (independent of temperature)

P 12-21

The irreversible liquid-phase reactions

Reaction 1:

Reaction 2:

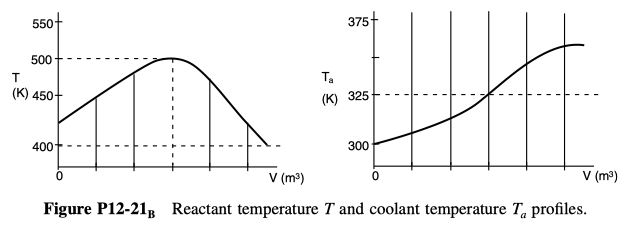

are carried out in a PFR with heat exchange. The following temperature profiles were obtained for the reactor and the coolant stream:

The concentrations of A, B, C, and D were measured at the point down the reactor where the liquid temperature, T, reached a maximum, and they were found to be CA = 0.1, CB = 0.2, CC= 0.5, and CD= 1.5, all in mol/dm3. The product of the overall heat-transfer coefficient and the heat-exchanger area per unit volume, Ua, is 10 . The entering molar flow rate of A is 10 mol/s.

Additional information

,

; at 400 K

;

- What is the activation energy for Reaction (1)?

Citation

@online{utikar2024,

author = {Utikar, Ranjeet},

title = {Workshop 07: {Non-isothermal} Reactor Design},

date = {2024-04-02},

url = {https://cre.smilelab.dev/content/workshops/07-non-isothermal-reactor-design/},

langid = {en}

}