Workshop 02: Conversion and reactor sizing

Lecture notes for chemical reaction engineering

Try following problems from Fogler 5e(Fogler 2016).

P2-3, P2-4, P2-7, P2-10.

We will go through some of these problems in the workshop.

A collab notebook that contains specimen code can be obtained by clicking on link below.

Solutions to these problems are uploaded at Workshop 2 solutions

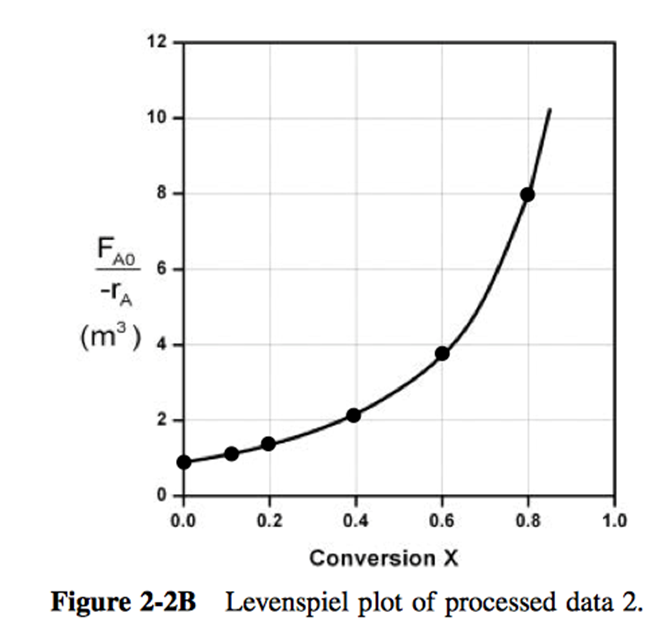

- P2-3: You have two CSTRs and two PFRs, each with a volume of . Use Figure 1 to calculate the conversion for each of the reactors in the following arrangements.

Two CSTRs in series.

Two PFRs in series.

Two CSTRs in parallel with the feed, , divided equally between the two reactors.

Two PFRs in parallel with the feed divided equally between the two reactors.

A CSTR and a PFR in parallel with the flow equally divided. Calculate the overall conversion,

with

and

A PFR followed by a CSTR.

A CSTR followed by a PFR.

A PFR followed by two CSTRs. Is this arrangement a good arrangement or is there a better one?

The data from Figure 1 is provided in file workshop-02-problem-1-data.csv

P2-4: The exothermic reaction of stillbene (A) to form the economically important trospophene (B) and methane (C), i.e.,

was carried out adiabatically and the following data recorded:

The entering molar flow rate of A was .

- What are the PFR and CSTR volumes necessary to achieve 40% conversion?

- Over what range of conversions would the CSTR and PFR reactor volumes be identical?

- What is the maximum conversion that can be achieved in a CSTR?

- What conversion can be achieved if a PFR is followed in series by a CSTR?

- What conversion can be achieved if a CSTR is followed in a series by a PFR?

- Plot the conversion and rate of reaction as a function of PFR reactor volume up to a volume of .

The data from Table 1 is provided in file workshop-02-problem-2.csv

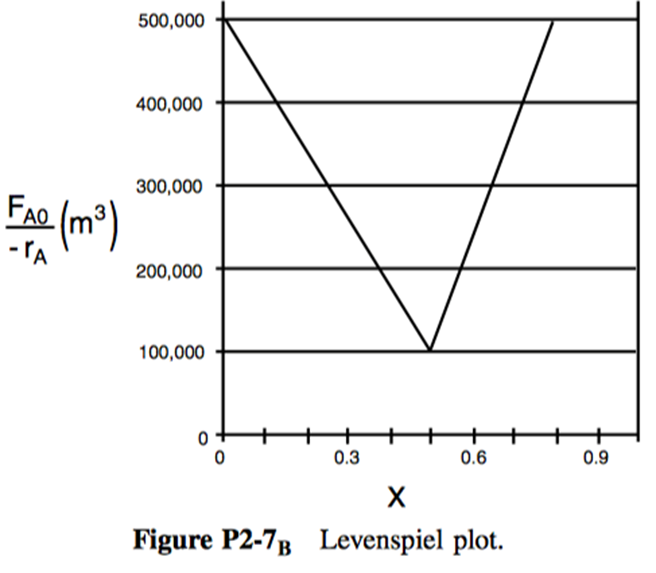

P2-7: The adiabatic exothermic irreversible gas-phase reaction

is to be carried out in a flow reactor for an equimolar feed of A and B. A Levenspiel plot for this reaction is shown in Figure 2 .

- What PFR volume is necessary to achieve 50% conversion?

- What CSTR volume is necessary to achieve 50% conversion?

- What is the volume of a second CSTR added in series to the first CSTR (Part b) necessary to achieve an overall conversion of 80%?

- What PFR volume must be added to the first CSTR (Part b) to raise the conversion to 80%?

- What conversion can be achieved in a CSTR? In a PFR?

- Think critically to critique the answers (numbers) to this problem.

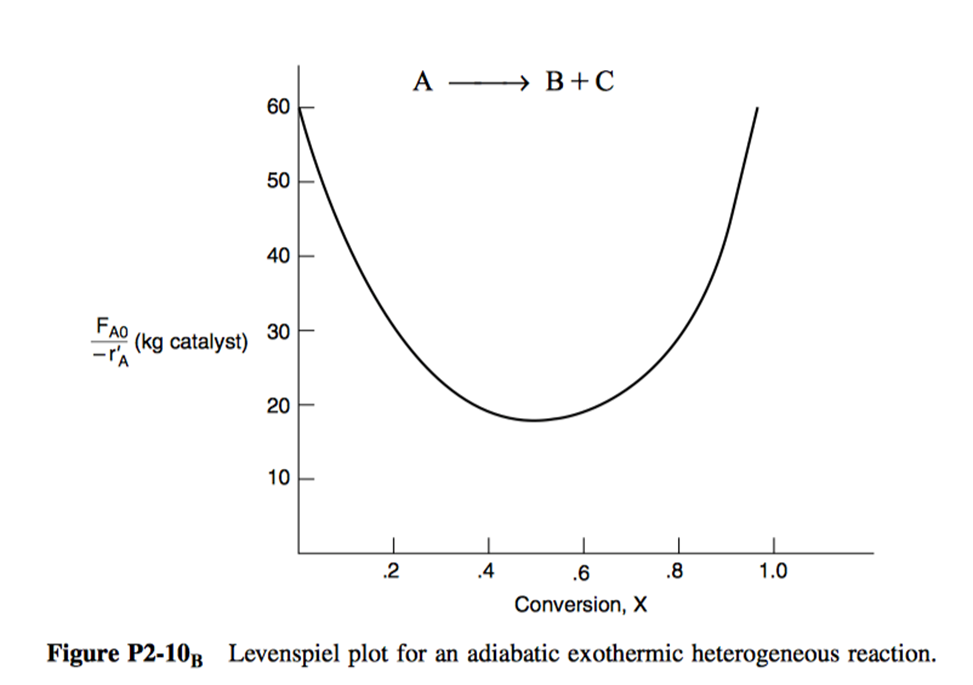

P2.10: The curve shown in Figure 3 is typical of a gas-solid catalytic exothermic reaction carried out adiabatically.

- Assuming that you have a fluidized CSTR and a PBR containing equal weights of catalyst, how should they be arranged for this adiabatic reaction? Use the smallest amount of catalyst weight to achieve 80% conversion of A.

- What is the catalyst weight necessary to achieve 80% conversion in a fluidized CSTR?

- What fluidized CSTR weight is necessary to achieve 40% conversion?

- What PBR weight is necessary to achieve 80% conversion?

- What PBR weight is necessary to achieve 40% conversion?

- Plot the rate of reaction and conversion as a function of PBR catalyst weight, W.

Additional information: FA0 = 2 mol/s.

The data from Figure 3 is provided in file workshop-02-problem-4.csv

References

Citation

@online{utikar2024,

author = {Utikar, Ranjeet},

title = {Workshop 02: {Conversion} and Reactor Sizing},

date = {2024-02-28},

url = {https://cre.smilelab.dev/content/workshops/02-conversion-and-reactor-sizing/},

langid = {en}

}