Group Project: chemical reaction engineering S1 2024

Compact steam methane reformer for on-site hydrogen supply

Introduction

Hydrogen is rapidly emerging as a key player in the global shift toward clean energy. Hydrogen fueling stations are critical to this transition, especially as the demand for compact and efficient fueling solutions grows alongside the rise in fuel cell vehicles (FCVs). These stations represent a significant advancement in refueling infrastructure, offering fast, high-density energy solutions compatible with the increasing pace of modern transportation. While the industry is still evolving and grappling with challenges related to innovation and technology scaling, the development of more compact hydrogen fueling options could significantly accelerate the adoption of hydrogen as a mainstream energy source and drive further advancements in sustainable transport.

On-site hydrogen production through steam-methane reforming (SMR) from city gas or natural gas is believed to be a cost-effective way for hydrogen-based infrastructure due to high cost of hydrogen transportation (C. Zhang et al. (2022)).

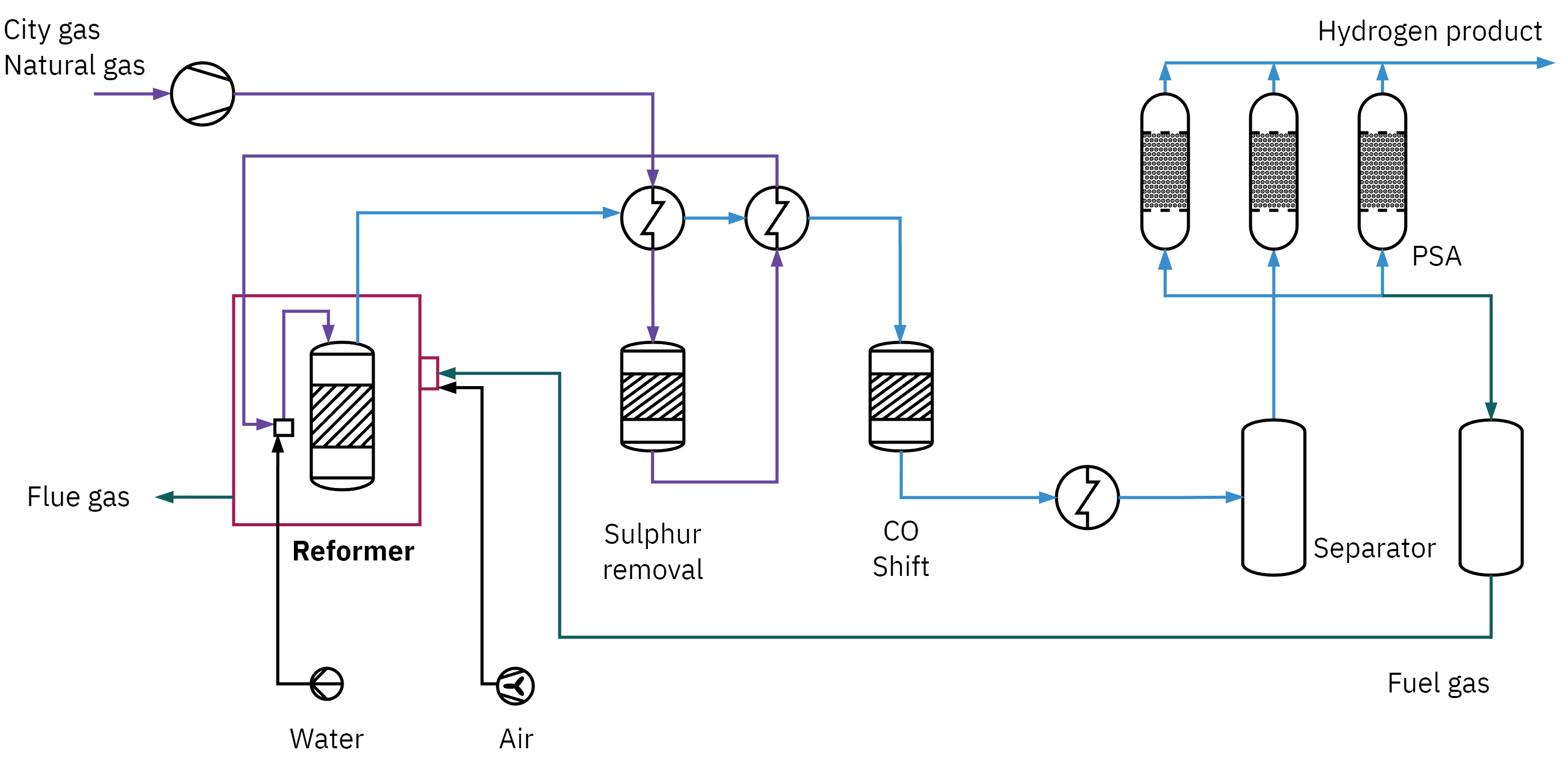

Compact hydrogen production systems on-site typically involve a series of processes: steam-methane reforming (SMR), water-gas shift (WGS), and pressure swing adsorption (PSA). If the system uses urban gas as a feedstock, it necessitates a desulfurization step to lower sulfur content to ppm levels. This precaution helps to prevent potential detrimental impacts on the catalysts used in both the reforming and shift reactions and maintains the integrity of the hydrogen production process. A typical process is shown in Figure 1.

Steam methane reforming occurs in reactors that are actually tubular furnaces (Worstell (2014)). A typical steam methane reformer preheats the gas feed in a convection furnace box, then injects the hot gas into vertical tubes placed in a radiation furnace box. The vertical tubes contain a nickel impregnated solid-supported catalyst (H. Zhang, Sun, and Hu (2021)). The catalyst-filled tubes are designed for a specified heat flux along the tube (Karpilov and Pashchenko (2023)).

Some other papers that you may find useful are (Bhat and Sadhukhan (2009), Mokheimer et al. (2014), Boyano et al. (2011), Lao et al. (2016), Ade et al. (2022), and Ma et al. (2022) )

Problem description

In this project, your team has been assigned the task of designing a fixed bed SMR reactor capable of generating 30 of hydrogen using city gas.

Your team will research on the SMR technology, design the SMR reactor, and explore strategies for control and optimization of the reactor.

A short note on reactors used for SMR

Based on literature survey, prepare a note on reaction engineering aspects of steam methane reforming. The references provided at the end may be used as a starting point for preparing such a note.

Design of SMR reactor

Design the SMR reactor to be operated at constant temperature. Consider all the major reactions occuring within the SMR process. Detailed kinetics of the reactions occuring is given by Hou and Hughes (2001). Using appropriate assumptions, follow the reaction engineering algorithm to develop (mass and energy) balance equations for both the reforming section and furnace section1. Use literature to obtain all the data required for completing your design.

Once your design is finalized, conduct a sensitivity study to assess the effect of various operating and design parameters (such as temperature, flow rate, etc.) on the hydrogen production. You can use the reactor model to perform these studies.

Explore possibilities for optimization (such as adjusting the conversion so that optimal amount of fuel gas is available to heat the SMR reactor) and comment on safety, and control of the reactor.

The project is deliberately set to be open‐ended. You are expected to do some self‐directed study of material outside of what has been covered in the unit.

Report

Prepare a report consisting of the following:

Reaction engineering aspects of steam methane reforming (20 marks)

Present a comprehensive note (5 – 6 pages) on the state of the art of steam methane reforming technology. Incude aspects of catalysis, novel configurations, operating conditions, etc.

Reactor design for production of 30 hydrogen (40 marks)

Optimization, safety, and control (20 marks)

Critical review (10 marks)

Present a critical review of your design activity. Some key guiding questions (not limited to) are: Why should we believe your design? What worked, What did not work? How to improve the design?

Marking

The report will be marked as follows:

| Description | Marks |

|---|---|

| Short note | 20 |

| Reaction engineering aspects of steam methane reforming | |

| Reactor design | 60 |

| Detailed reactor design | 40 |

| Optimization, safety, and control | 20 |

| Critical Review | 10 |

| Report Presentation | 10 |

| Total | 100 |

Report format

Use the following report format

Cover page

1.0 Executive Summary

2.0 Process Description

3.0 Reactor Design

3.1 Reaction chemistry and thermodynamics

3.2 Catalyst

3.3 Reactor type

3.4 Reactor sizing

3.5 Reactor operating conditions and sensitivities

3.6 Conversion and selectivity

3.7 Reactor concentration profiles

3.8 Materials of construction

5.0 Reactor optimization, safety, and control

6.0 Critical review

7.0 Conclusions and Recommendations

8.0 References

9.0 AppendicesSubmission

The project is conducted in a group of four. You are free to choose your group. Please notify the instructors of your groups as soon as you form them. If you cannot find a group, please get in touch with your instructor at the earliest. You will need to submit all the files created electronically on blackboard (Moodle for Miri students). There should be one submission per group. Please follow the instructions given below carefully for preparing the files for submission. Failure to follow these instructions may result in us not being able to assess the files.

You will be uploading two files.

Report (pdf file containing the report). You need to name the file as STUDENTID_CHEN3010_project_report.pdf (or ) STUDENTID_CHEN5040_project_report.pdf (Replace STUDENTID with your Student ID). You need to make only one submission per group.

Create a zip file named STUDENTID_CHEN3010_project_Supporting_files.zip. The zip file should contain a) All supporting files for design, modeling, and simulation activities (excel, python, …) presented in the PDF report file. You may upload the supporting file to a cloud storage of your preference and share a link with us.

References

Footnotes

Essentially, you are designing two reactors. These two reactors have different reactions taking place within them. You may also choose to model these two reactors as two different types (e.g. the reformer as a PBR, and the furnace as a CSTR)↩︎

Citation

@online{utikar,

author = {Utikar, Ranjeet},

url = {https://cre.smilelab.dev/admin/docs/project/Project_description_S1_2024.html},

langid = {en}

}