import numpy as np

from scipy.integrate import solve_ivp

from scipy.optimize import fsolve

import matplotlib.pyplot as plt

from IPython.display import display, Markdown

def batch_reactor(t, y, *args):

ca, cd, cu = y

k1, k2, k1A, k2A = args

r1a = k1 * (ca - cd/k1A)

r2a = k2 * (ca - cu/k2A)

dcadt = -r1a -r2a

dcddt = r1a

dcudt = r2a

return [dcadt, dcddt, dcudt]

k1 = 1.0 # 1/min

k2 = 100 # 1/min

k1A = 10.0

k2A = 1.5

ca0 = 1.0

# initial conditions

y0 = [ca0, 0, 0]

args = (k1, k2, k1A, k2A)

t_final = 12

sol = solve_ivp(batch_reactor, [0, t_final], y0, args=args, dense_output=True)

t = np.linspace(0,t_final, 1000)

ca, cd, cu = sol.sol(t)Solutions to workshop 06: Multiple reactions

Lecture notes for chemical reaction engineering

Try following problems from Fogler 5e (Fogler 2016). P 8-3, P 8-4, P 8-7, P 8-9

We will go through some of these problems in the workshop.

P 8-3

The following reactions

take place in a batch reactor.

Additional information:

= 1.0 min–1; = 10

= 100 min–1; = 1.5

= 1 mol/dm3

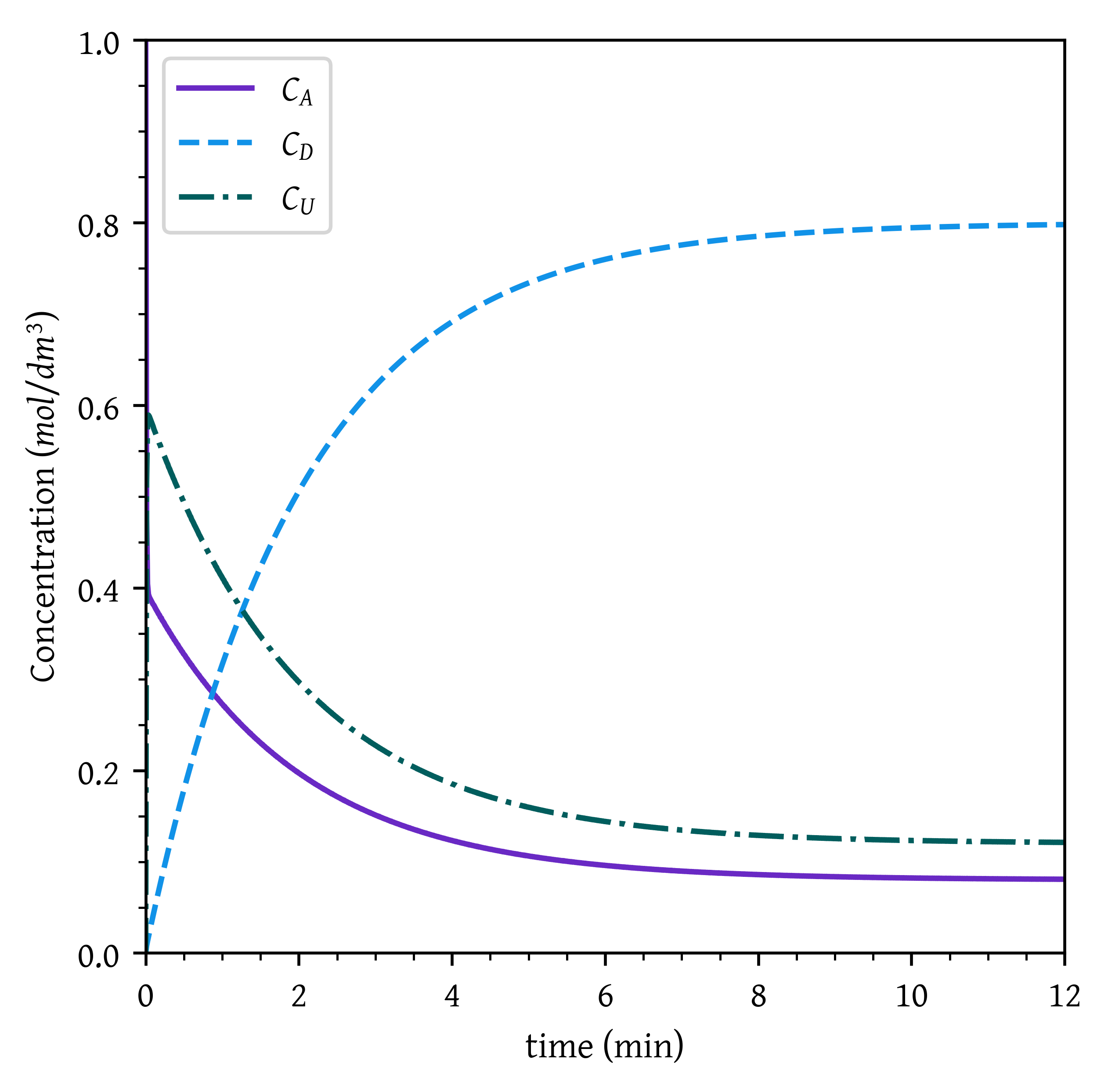

Plot and analyze conversion and the concentrations of A, D, and U as a function of time. When would you stop the reaction to maximize the concentration of D? Describe what you find.

When does the maximum concentration of U occur? (Ans.: t = 0.04 min)

What are the equilibrium concentrations of A, D, and U?

What would be the exit concentrations from a CSTR with a space time of 1.0 min? Of 10.0 min? Of 100 min?

plt.plot(t, ca, label='$C_A$')

plt.plot(t, cd, label='$C_D$')

plt.plot(t, cu, label='$C_U$')

plt.xlabel('time (min)')

plt.ylabel('Concentration ($mol/dm^3$)')

# Setting x and y axis limits

plt.xlim(0, t_final)

plt.ylim(0, ca0)

plt.legend()

plt.show()cumax_idx = np.argmax(cu)

tumax = t[cumax_idx]

cumax = cu[cumax_idx]Maximum concentration of U, = = 0.59 occurs at = 0.04 min

As keeps on increasing with time until the equilibrium is reached, To maximize , stop the reaction after equilibrium is reached.

cae = ca[-1]

cde = cd[-1]

cue = cu[-1]Equilibrium concentrations

= 0.08

= 0.80

= 0.12

def cstr(vars, *args):

ca, cd, cu = vars

t, k1, k2, k1A, k2A = args

r1a = k1 * (ca - cd/k1A)

r2a = k2 * (ca - cu/k2A)

eq1 = ca0 - ca - t * (r1a + r2a)

eq2 = -cd + t * r1a

eq3 = -cu + t * r2a

return [eq1, eq2, eq3]

initial_guess = [ca0, 0, 0]

times = [1, 10, 100]

md = ""

for tau in times:

args = (tau, k1, k2, k1A, k2A)

ca, cd, cu = fsolve(cstr, initial_guess, args=args)

md += (

f"At $\\tau$ = {tau:.2f} min.:\n"

f"$C_A$ = {ca:.2f} $mol/dm^3$,\n"

f"$C_D$ = {cd:.2f} $mol/dm^3$,\n"

f"$C_U$ = {cu:.2f} $mol/dm^3$ \n\n"

)

display(Markdown(md))At = 1.00 min.: = 0.30 , = 0.27 , = 0.44

At = 10.00 min.: = 0.13 , = 0.67 , = 0.20

At = 100.00 min.: = 0.09 , = 0.78 , = 0.13

P 8-4

Consider the following system of gas-phase reactions:

B is the desired product, and X and Y are foul pollutants that are expensive to get rid of. The specific reaction rates are at 27 C. The reaction system is to be operated at 27 C and 4 atm. Pure A enters the system at a volumetric flow rate of 10 dm3/min.

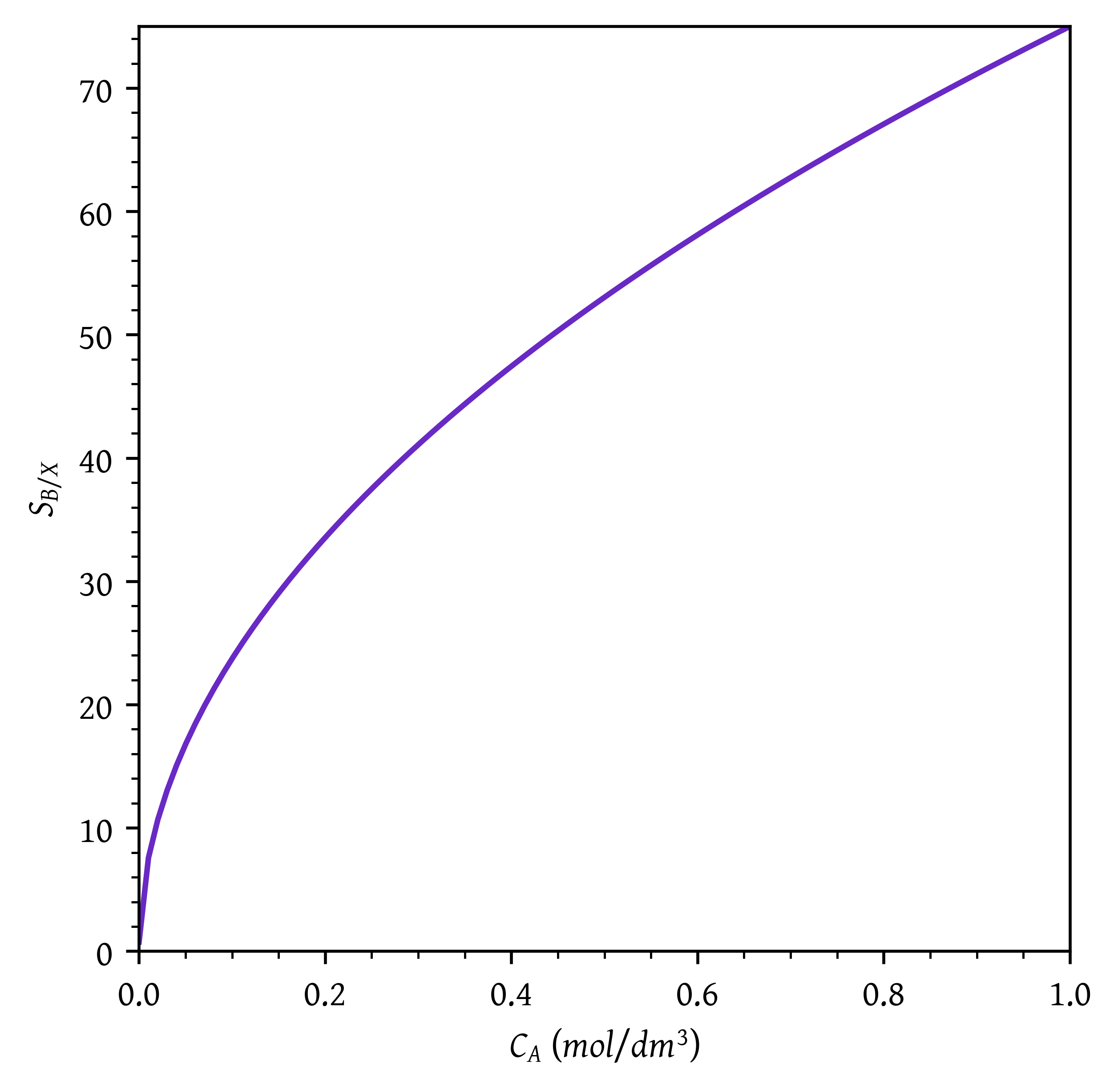

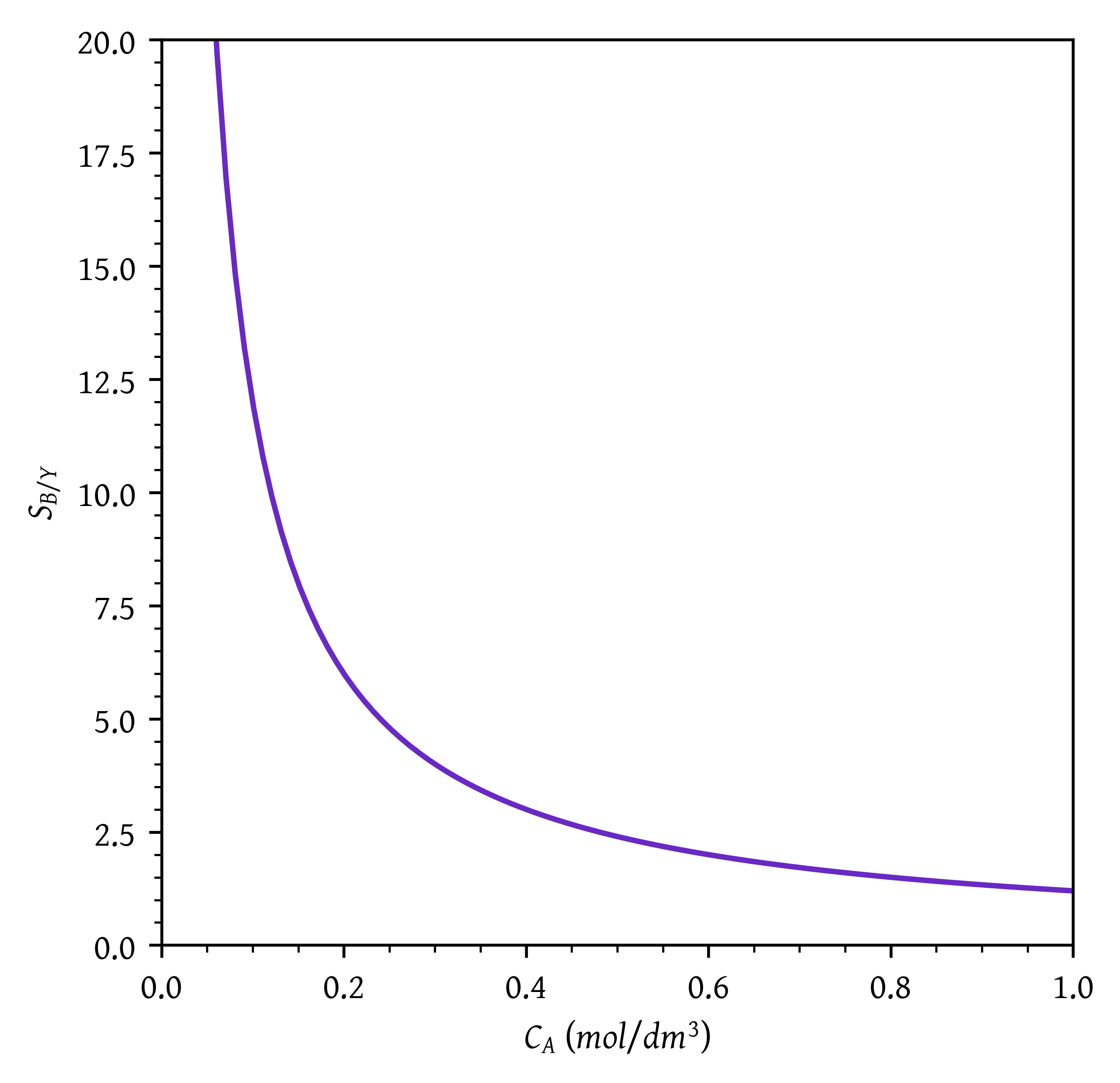

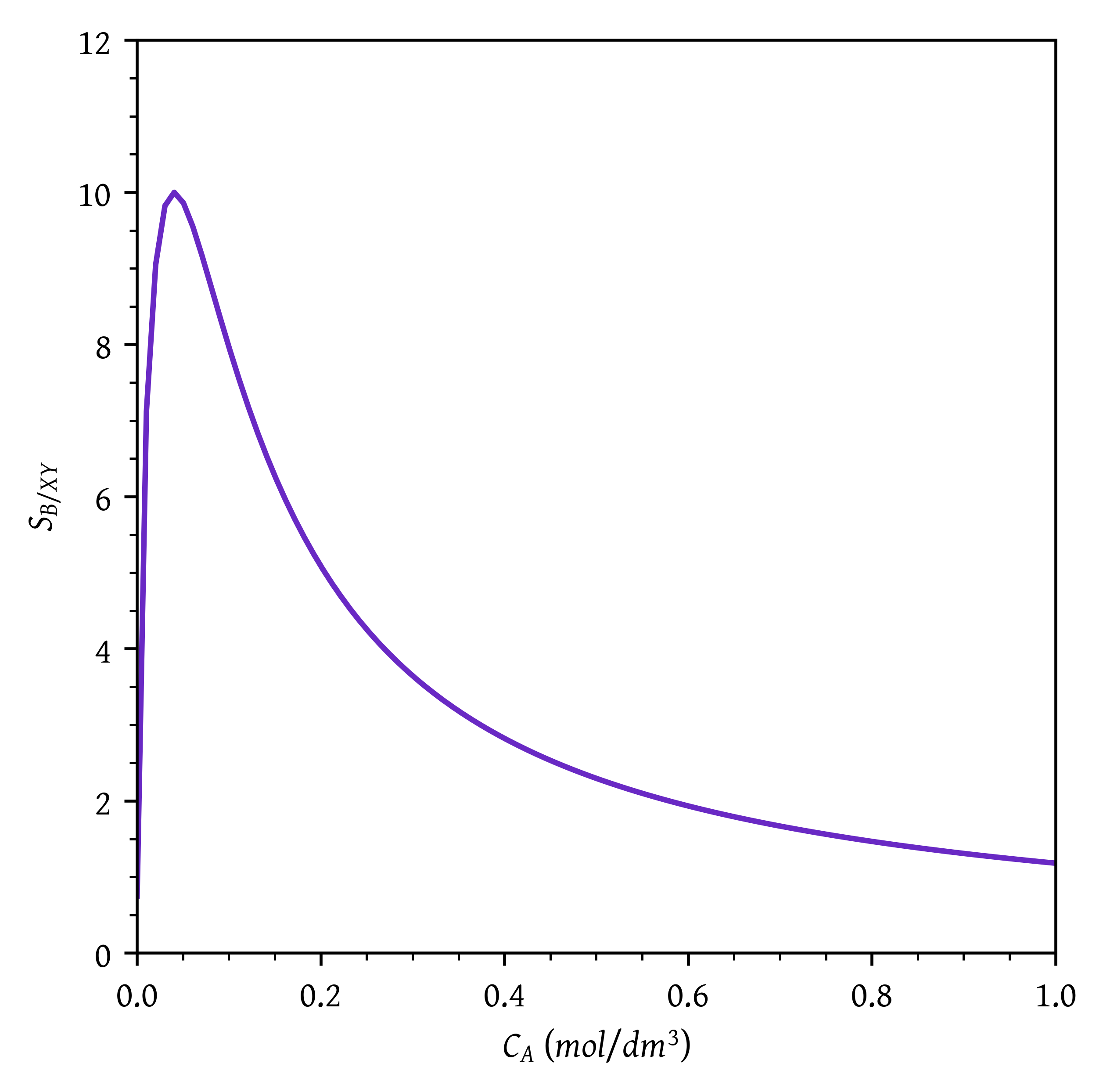

Sketch the instantaneous selectivities as a function of the concentration of CA.

Consider a series of reactors. What should be the volume of the first reactor?

What are the effluent concentrations of A, B, X, and Y from the first reactor?

What is the conversion of A in the first reactor?

If 99% conversion of A is desired, what reaction scheme and reactor sizes should you use to maximize ?

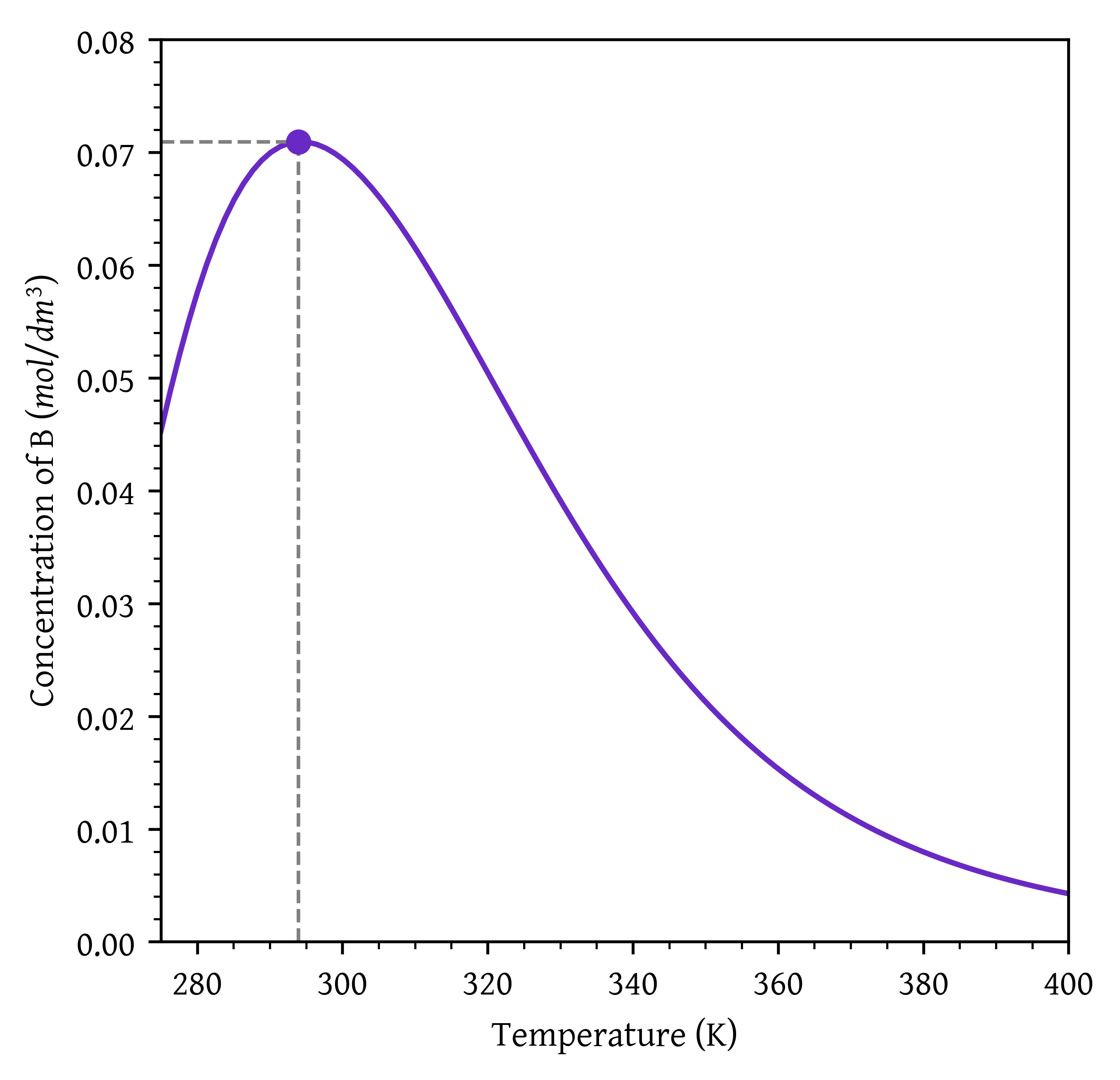

Suppose that E1 = 20,000 cal/mol, E2=10,000 cal/mol, and E3=30,000 cal/mol. What temperature would you recommend for a single CSTR with a space time of 10 min and an entering concentration of A of 0.1 mol/dm3 ?

import numpy as np

from scipy.integrate import solve_ivp

from scipy.optimize import fsolve

from scipy.optimize import minimize_scalar

from scipy.integrate import quad

import matplotlib.pyplot as plt

from IPython.display import display, Markdown

rx = lambda ca: 0.004 * ca**0.5

rb = lambda ca: 0.3 * ca

ry = lambda ca: 0.25 * ca**2

sbx = lambda ca: rb(ca)/rx(ca)

sby = lambda ca: rb(ca)/ry(ca)

sbxy = lambda ca: rb(ca)/(rx(ca) + ry(ca))

ca = np.linspace(1e-4,1,100)plt.plot(ca,sbx(ca))

plt.xlabel('$C_A$ ($mol/dm^3$)')

plt.ylabel('$S_{B/X}$')

# Setting x and y axis limits

plt.xlim(0, ca[-1])

plt.ylim(0, np.ceil(sbx(ca[-1])))

plt.show()plt.plot(ca,sby(ca))

plt.xlabel('$C_A$ ($mol/dm^3$)')

plt.ylabel('$S_{B/Y}$')

# Setting x and y axis limits

plt.xlim(0, ca[-1])

plt.ylim(0, 20)

plt.show()plt.plot(ca,sbxy(ca))

plt.xlabel('$C_A$ ($mol/dm^3$)')

plt.ylabel('$S_{B/XY}$')

# Setting x and y axis limits

plt.xlim(0, ca[-1])

plt.ylim(0, 12)

plt.show()# Maximize S_B/XY

bounds=(1e-4, 1)

# Maximize the selectivity by minimizing the negative of the selectivity function

result = minimize_scalar(lambda ca: -sbxy(ca), method='bounded', bounds=bounds)

camax = result.x

sbxy_max = sbxy(camax)Maximum concentration of A, = 0.04

Maximum selectivity = 10.00

The CSTR operates at exit concentration of 0.04

T = 27 + 273.15 # K

v0 = 10 # dm^3/min

P = 4 # atm

ya0 = 1 # pure A

R = 0.082

ca0 = ya0 * P /(R * T)

rate = rx(camax) + rb(camax) + ry(camax)

v_cstr = v0 * (ca0 - camax)/ rate- = 0.163

- = 92.81

tau_cstr = v_cstr/v0

cb_cstr = tau_cstr* rb(camax)

cx_cstr = tau_cstr* rx(camax)

cy_cstr = tau_cstr* ry(camax)Exit concentration of CSTR

- = 1.114e-01

- = 7.425e-03

- = 3.713e-03

x_cstr = (ca0 - camax)/ca0Conversion in first reactor = 0.75

fa0 = ca0*v0

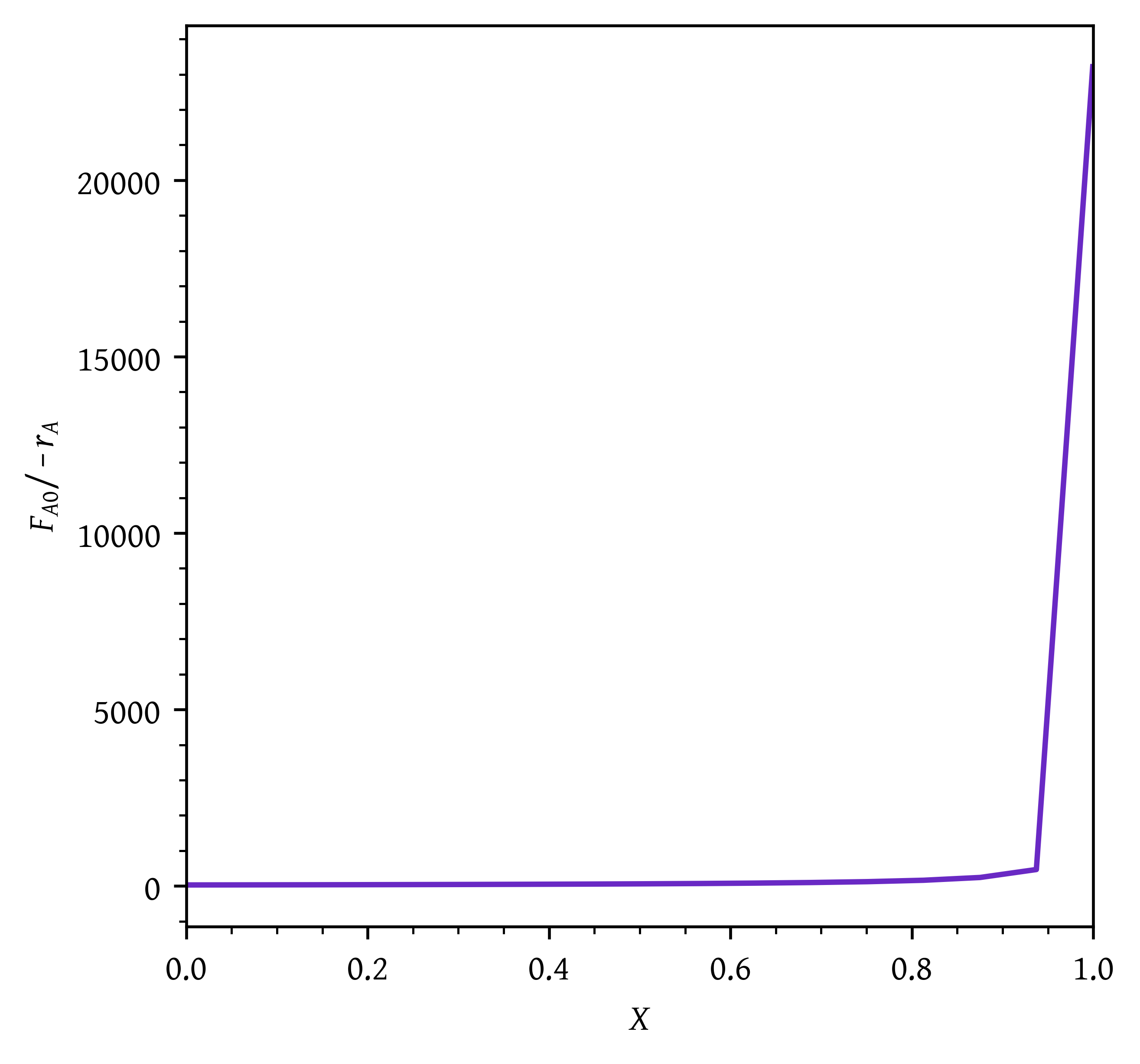

fa0_by_ra = fa0/(rb(ca) + rx(ca) + ry(ca))

x = (ca0 - ca)/ca0

plt.plot(x,fa0_by_ra)

plt.xlabel('$X$')

plt.ylabel('$F_{A0}/-r_A$')

# Setting x and y axis limits

plt.xlim(0, 1)

# plt.ylim(0, 10000)

plt.show()def pfr(x, *args):

fa0 = args[0]

ca = ca0 * (1 - x)

return fa0/(rb(ca) + rx(ca) + ry(ca))

x_start = x_cstr

x_end = 0.99

v_pfr, _ = quad(pfr, x_start, x_end, args=(fa0))PFR volume required to achieve final conversion of 0.99 = 91.18

e1 = 20000

e2 = 10000

e3 = 30000

k1 = lambda T: 0.004 * np.exp((e1/1.98) * ((1/T) - (1/300)))

k2 = lambda T: 0.3 * np.exp((e2/1.98) * ((1/T) - (1/300)))

k3 = lambda T: 0.25 * np.exp((e3/1.98) * ((1/T) - (1/300)))

rxt = lambda ca,T: k1(T) * ca**0.5

rbt = lambda ca,T: k2(T) * ca

ryt = lambda ca,T: k3(T) * ca**2

sbxt = lambda ca,T: rbt(ca,T)/rxt(ca,T)

sbyt = lambda ca,T: rbt(ca,T)/ryt(ca,T)

sbxyt = lambda ca,T: rbt(ca,T)/(rxt(ca,T) + ryt(ca,T))

tau = 10

ca0 = 0.1

initial_guess = [ca0, 0, 0, 0]

def cstr_btx(vars, *args):

ca, cx, cb, cy = vars

tau, T = args

r1 = rxt(ca,T)

r2 = rbt(ca,T)

r3 = ryt(ca,T)

eq1 = ca0 - ca - tau * (r1 + r2 + r3)

eq2 = -cx + tau * r1

eq3 = -cb + tau * r2

eq4 = -cy + tau * r3

return [eq1, eq2, eq3, eq4]

# Function to solve the CSTR equations for a given temperature

def maximize_cb(T):

args = (tau, T)

ca, cx, cb, cy = fsolve(cstr_btx, initial_guess, args=args)

return -cb

result = minimize_scalar(maximize_cb, bounds=(275, 400), method='bounded')

optimal_temp = result.x

max_cb = -result.fun

temps = np.linspace(275,400,100)

cb_values = []

for temp in temps:

args = (tau, temp)

ca, cx, cb, cy = fsolve(cstr_btx, initial_guess, args=args)

cb_values.append(cb)

cb_values = np.array(cb_values)

temps = np.array(temps)

max_cb_index = np.argmax(cb_values)

max_cb_temp = temps[max_cb_index]

max_cb = cb_values[max_cb_index]

plt.plot(temps, cb_values)

plt.scatter([max_cb_temp], [max_cb], zorder=5)

# plt.axvline(x=max_cb_temp, color='gray', linestyle='--', lw=1)

# plt.axhline(y=max_cb, color='gray', linestyle='--', lw=1)

plt.plot([max_cb_temp, max_cb_temp], [0, max_cb], color='gray', linestyle='--', lw=1) # Vertical line to curve

plt.plot([min(temps), max_cb_temp], [max_cb, max_cb], color='gray', linestyle='--', lw=1) # Horizontal line to curve

plt.xlabel('Temperature (K)')

plt.ylabel('Concentration of B ($mol/dm^3$)')

# Setting x and y axis limits

plt.xlim(275, 400)

plt.ylim(0, 0.08)

plt.show()

- Optimal temperature for maximizing = 294.26 K. Maximum = 0.07

P 8-9

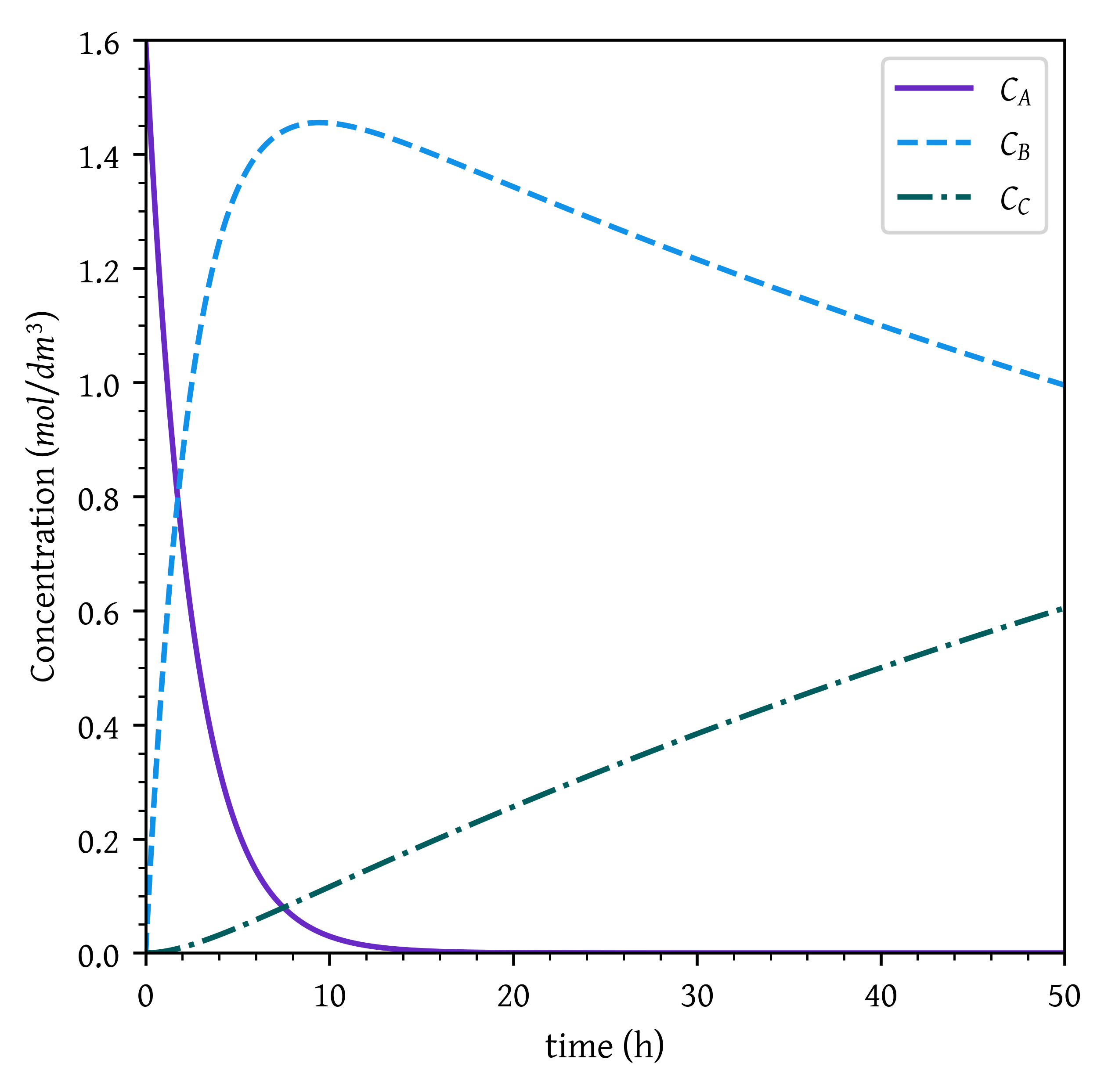

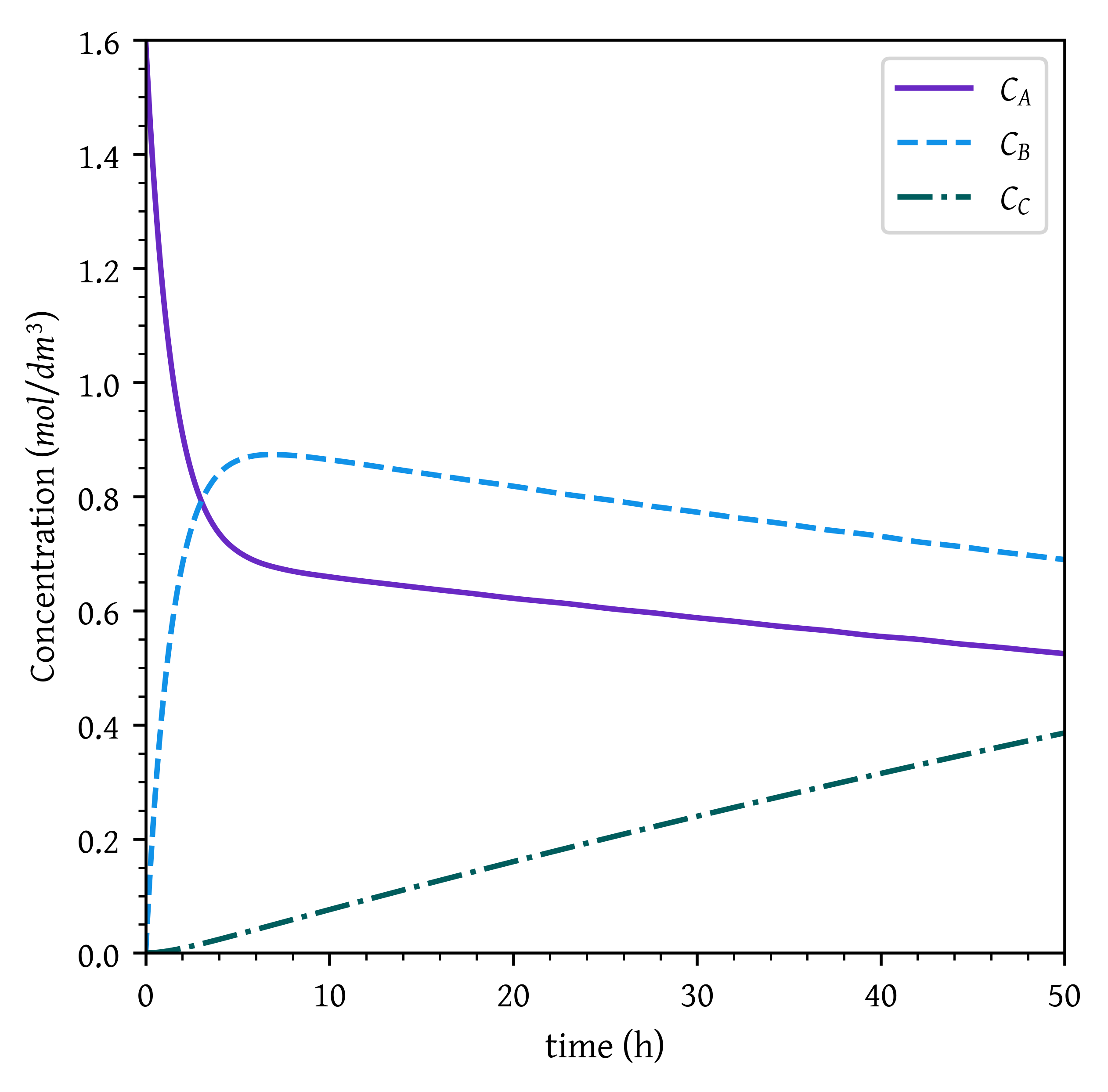

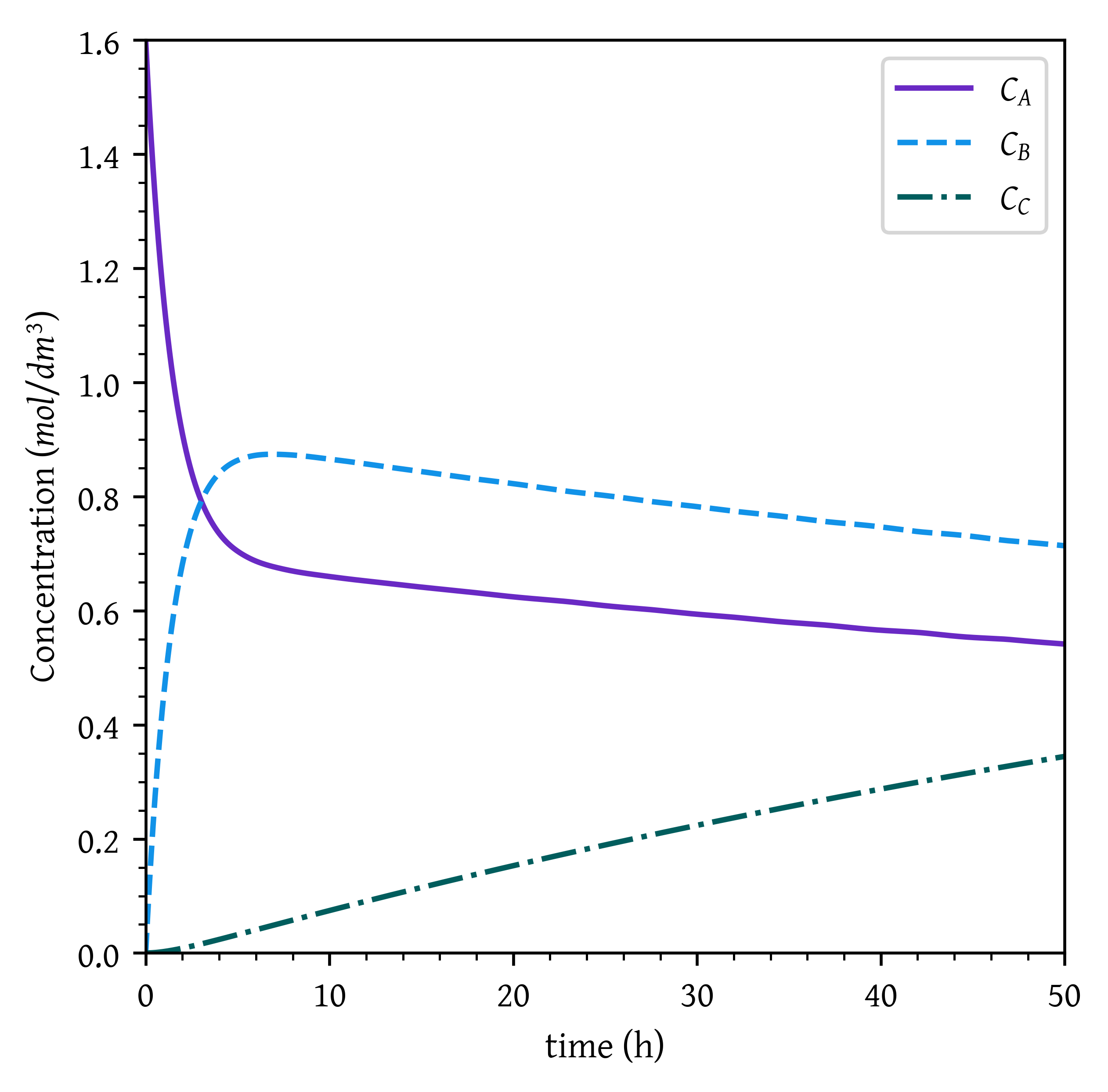

The elementary liquid-phase series reaction

is carried out in a 500-dm3 batch reactor. The initial concentration of A is 1.6 mol/dm3. The desired product is B, and separation of the undesired product C is very difficult and costly. Because the reaction is carried out at a relatively high temperature, the reaction is easily quenched.

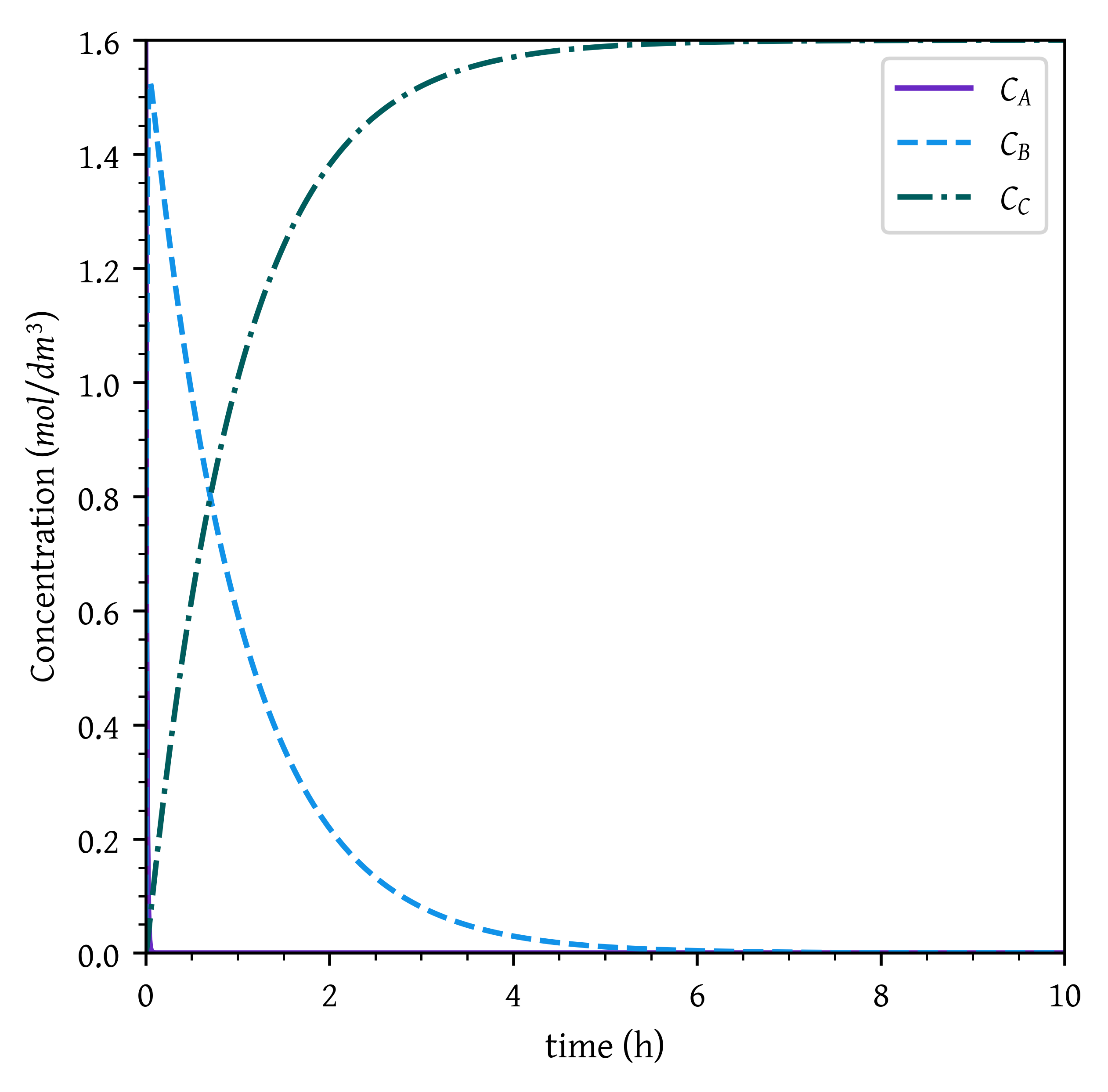

Plot and analyze the concentrations of A, B, and C as a function of time. Assume that each reaction is irreversible, with and .

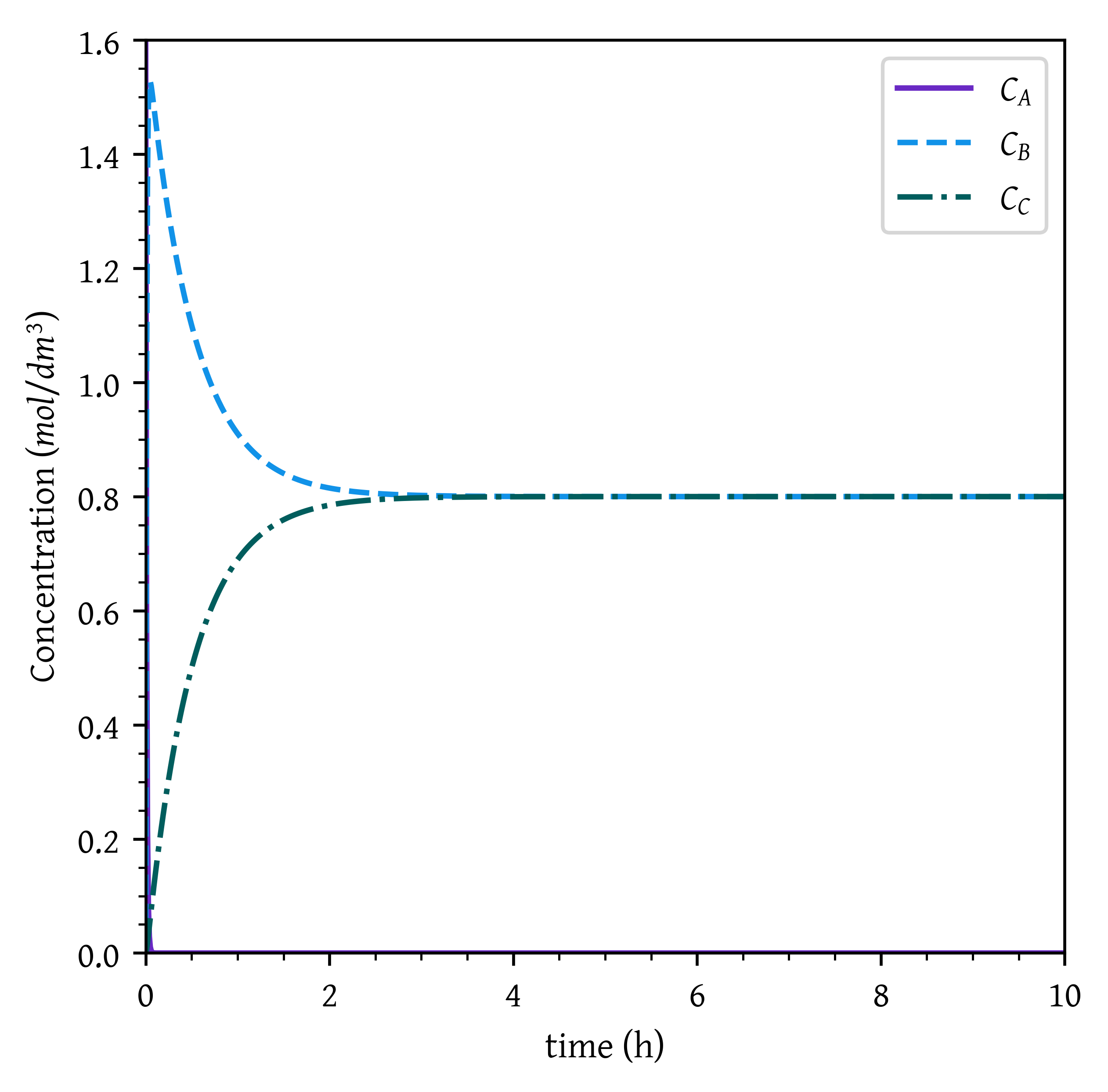

Plot and analyze the concentrations of A, B, and C as a function of time when the first reaction is reversible, with .

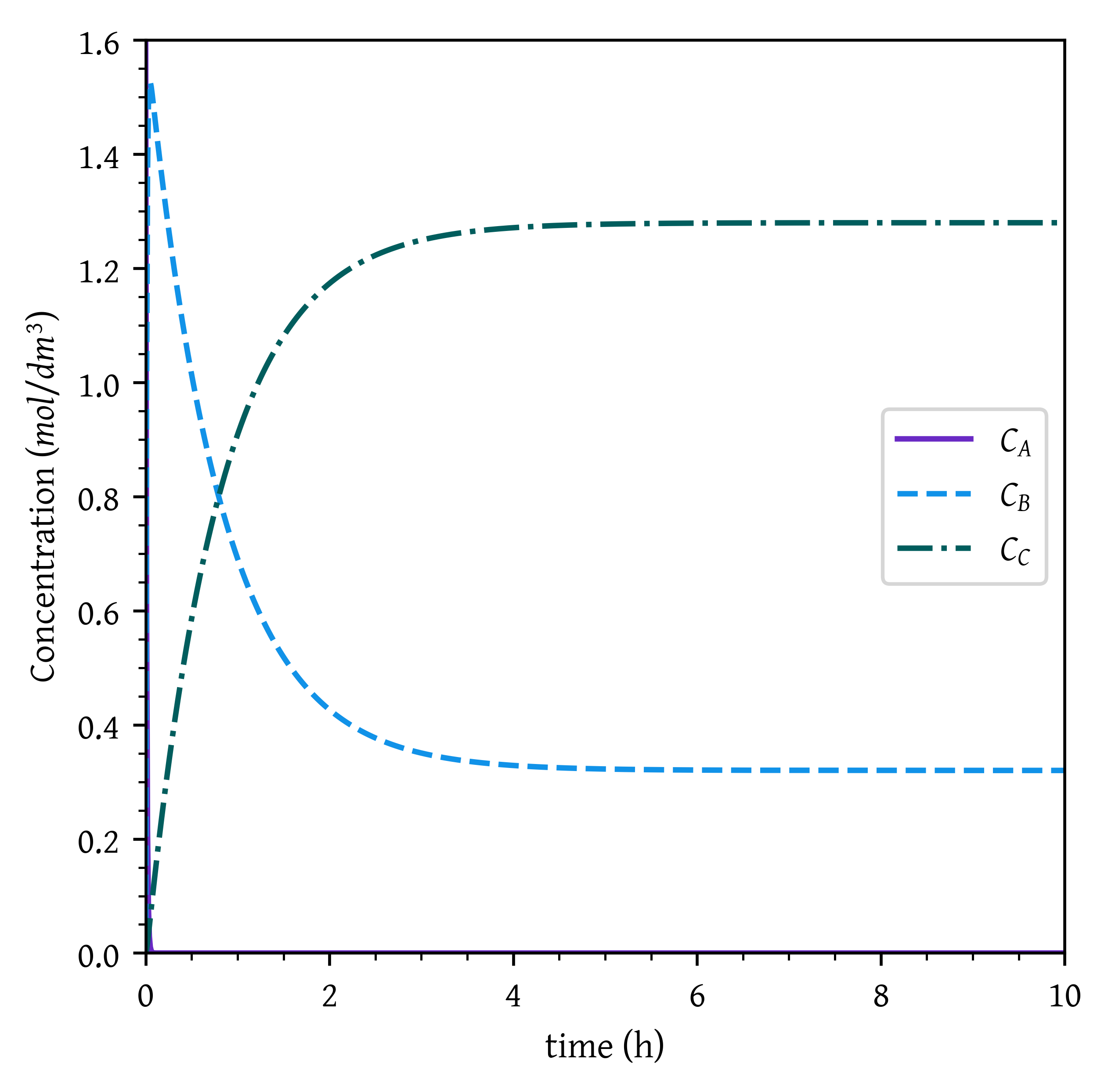

Plot and analyze the concentrations of A, B, and C as a function of time for the case where both reactions are reversible, with .

Compare (a), (b), and (c) and describe what you find.

Vary . Explain the consequence of and and with and with , and .

import numpy as np

from scipy.integrate import solve_ivp

import matplotlib.pyplot as plt

def batch_reactor_a(t, y, *args):

ca, cb, cc = y

k1, k2 = args

r1a = k1 * ca

r2b = k2 * cb

dcadt = - r1a

dcbdt = r1a - r2b

dccdt = r2b

return [dcadt, dcbdt, dccdt]

k1 = 0.4 # 1/h

k2 = 0.01

ca0 = 1.6

# initial conditions

y0 = [ca0, 0, 0]

args = (k1, k2)

t_final = 50

sol = solve_ivp(batch_reactor_a, [0, t_final], y0, args=args, dense_output=True)

t = np.linspace(0,t_final, 1000)

ca, cb, cc = sol.sol(t)plt.plot(t, ca, label='$C_A$')

plt.plot(t, cb, label='$C_B$')

plt.plot(t, cc, label='$C_C$')

plt.xlabel('time (h)')

plt.ylabel('Concentration ($mol/dm^3$)')

# Setting x and y axis limits

plt.xlim(0, t_final)

plt.ylim(0, ca0)

plt.legend()

plt.show()def batch_reactor_b(t, y, *args):

ca, cb, cc = y

k1, k2, km1 = args

r1a = k1 * ca

r1b = km1 * cb

r2b = k2 * cb

dcadt = - r1a + r1b

dcbdt = r1a -r1b - r2b

dccdt = r2b

return [dcadt, dcbdt, dccdt]

km1 = 0.3

# initial conditions

y0 = [ca0, 0, 0]

args = (k1, k2, km1)

t_final = 50

sol = solve_ivp(batch_reactor_b, [0, t_final], y0, args=args, dense_output=True)

t = np.linspace(0,t_final, 1000)

ca, cb, cc = sol.sol(t)plt.plot(t, ca, label='$C_A$')

plt.plot(t, cb, label='$C_B$')

plt.plot(t, cc, label='$C_C$')

plt.xlabel('time (h)')

plt.ylabel('Concentration ($mol/dm^3$)')

# Setting x and y axis limits

plt.xlim(0, t_final)

plt.ylim(0, ca0)

plt.legend()

plt.show()def batch_reactor_c(t, y, *args):

ca, cb, cc = y

k1, k2, km1, km2 = args

r1a = k1 * ca

r1b = km1 * cb

r2b = k2 * cb

r2c = km2 * cc

dcadt = - r1a + r1b

dcbdt = r1a -r1b - r2b + r2c

dccdt = r2b - r2c

return [dcadt, dcbdt, dccdt]

km1 = 0.3

km2 = 0.005

# initial conditions

y0 = [ca0, 0, 0]

args = (k1, k2, km1, km2)

t_final = 50

sol = solve_ivp(batch_reactor_c, [0, t_final], y0, args=args, dense_output=True)

t = np.linspace(0,t_final, 1000)

ca, cb, cc = sol.sol(t)plt.plot(t, ca, label='$C_A$')

plt.plot(t, cb, label='$C_B$')

plt.plot(t, cc, label='$C_C$')

plt.xlabel('time (h)')

plt.ylabel('Concentration ($mol/dm^3$)')

# Setting x and y axis limits

plt.xlim(0, t_final)

plt.ylim(0, ca0)

plt.legend()

plt.show()k1 = 100

k2 = 1

km1 = 0

km2 = 0

# initial conditions

y0 = [ca0, 0, 0]

args = (k1, k2, km1, km2)

t_final = 10

sol = solve_ivp(batch_reactor_c, [0, t_final], y0, args=args, dense_output=True)

t = np.linspace(0,t_final, 1000)

ca, cb, cc = sol.sol(t)

plt.plot(t, ca, label='$C_A$')

plt.plot(t, cb, label='$C_B$')

plt.plot(t, cc, label='$C_C$')

plt.xlabel('time (h)')

plt.ylabel('Concentration ($mol/dm^3$)')

# Setting x and y axis limits

plt.xlim(0, t_final)

plt.ylim(0, ca0)

plt.legend()

plt.show()When > 100, the first reaction is very fast. Therefore, all A is immediately converted to B and the concentration of B immediately reaches close to .

As < 0.1, the second reaction is much slower. Since both the reactions are irreversible (, and both are zero), B gets slowly converted to C. Given sufficient time, all B is converted to C.

k1 = 100

k2 = 1

km1 = 0

km2 = 1

# initial conditions

y0 = [ca0, 0, 0]

args = (k1, k2, km1, km2)

t_final = 10

sol = solve_ivp(batch_reactor_c, [0, t_final], y0, args=args, dense_output=True)

t = np.linspace(0,t_final, 1000)

ca, cb, cc = sol.sol(t)

plt.plot(t, ca, label='$C_A$')

plt.plot(t, cb, label='$C_B$')

plt.plot(t, cc, label='$C_C$')

plt.xlabel('time (h)')

plt.ylabel('Concentration ($mol/dm^3$)')

# Setting x and y axis limits

plt.xlim(0, t_final)

plt.ylim(0, ca0)

plt.legend()

plt.show()Since second reaction is reversible and , a steady state (equilibrium) is achieved where

k1 = 100

k2 = 1

km1 = 0

km2 = 0.25

# initial conditions

y0 = [ca0, 0, 0]

args = (k1, k2, km1, km2)

t_final = 10

sol = solve_ivp(batch_reactor_c, [0, t_final], y0, args=args, dense_output=True)

t = np.linspace(0,t_final, 1000)

ca, cb, cc = sol.sol(t)

plt.plot(t, ca, label='$C_A$')

plt.plot(t, cb, label='$C_B$')

plt.plot(t, cc, label='$C_C$')

plt.xlabel('time (h)')

plt.ylabel('Concentration ($mol/dm^3$)')

# Setting x and y axis limits

plt.xlim(0, t_final)

plt.ylim(0, ca0)

plt.legend()

plt.show(), Therefore at equilibrium is achieved where

At equilibrium = 0.32 , = 1.28

References

Citation

@online{utikar2024,

author = {Utikar, Ranjeet},

title = {Solutions to Workshop 06: {Multiple} Reactions},

date = {2024-03-24},

url = {https://cre.smilelab.dev/content/workshops/06-multiple-reactions/solutions.html},

langid = {en}

}