T = 150 + 273.15

TR = 25 + 273.15

hf_nh3 = -11020

hf_n2 = 0

hf_h2 = 0

# N2 + 3H2 -> 2 NH3

nu_n2 = -1

nu_h2 = -3

nu_nh3 = 2

# Getting the Cp values from Perry's handbook (@green2019)

cp_h2 = 6.992 # cal/mol H2 K

cp_n2 = 6.984 # cal/mol N2 K

cp_nh3 = 8.92 # cal/mol NH3 K

delta_h_tr = (nu_nh3 * hf_nh3) + (nu_n2 * hf_n2 + nu_h2 * hf_h2)

delta_cp = (nu_nh3 * cp_nh3) + (nu_n2 * cp_n2 + nu_h2 * cp_h2)

delta_h = delta_h_tr + delta_cp * (T - TR)

cal = 4.184 # J

delta_h_kj = cal * delta_h_tr + delta_cp * (T - TR)In class activity: Non-isothermal reactor design

Lecture notes for chemical reaction engineering

Heat of reaction

Calculate the heat of reaction for the synthesis of ammonia from hydrogen and nitrogen at 150 °C in kcal/mol of N2 reacted and also in kJ/mol of H2 reacted.

The enthalpy of formation of ammonia at 25 °C is

The enthalpy of formations at 25 °C

Heats of formation of pure components are 0.

Getting the values from Perry’s handbook (Green and Southard (2019))

= 6.992 ; = 6.984 ; = 8.92

= -22.04

at 423.15 K = -93.48

at 423.15 K = -31.16

Adiabatic Liquid-Phase Isomerization of Normal Butane

Normal butane, , is to be isomerized to isobutane in a plug-flow reactor. Isobutane is a valuable product that is used in the manufacture of gasoline additives. For example, isooctane can be further reacted to form iso-octane. The 2014 selling price of n-butane was $1.5/gal, while the trading price of isobutane was $1.75/gal.

This elementary reversible reaction is to be carried out adiabatically in the liquid phase under high pressure using essentially trace amounts of a liquid catalyst that gives a specific reaction rate of at . The feed enters at .

Calculate the PFR volume necessary to process () at conversion of a mixture -butane and -pentane, which is considered an inert.

Plot and analyze , , , and down the length of the reactor.

Calculate the CSTR volume for conversion.

Additional information:

-butane,

Activation energy =

at ,

Butane: ;

i-Pentane:

PFR algorithm

- Mole balance

- Rate law

- Stoichiometry

- Energy balance

From problem statement:

Adiabatic: = 0

No work: = 0

= 141 - 141 = 0

Substituting in Equation 7

- Solve

Solve equations 1 to 7 simultaneously.

import numpy as np

import matplotlib.pyplot as plt

from scipy.integrate import solve_ivp

# Constants

K0 = 31.1 # 1/h

T_K0 = 360 # K

KC0 = 3.3

T_KC0 = 60 + 273.15 # K

E = 65700 # J/mol

R = 8.314 # J/mol K

DELTAHR = -6900 # J/mol

def adiabatic_pfr( V, y, *args ):

X = y[0]

(fa0,ca0, T0, theta, cp) = args

sum_cp = np.sum(theta * cp)

T = T0 + (-DELTAHR) * X / sum_cp

k = K0 * np.exp((E/R) * (1/T_K0 - 1/T))

Kc = KC0 * np.exp((DELTAHR/R) * (1/T_KC0 - 1/T))

ca = ca0 * ( 1 - X )

cb = ca0 * X

rate = k * (ca - cb/Kc)

dXdV = rate/fa0

return dXdV

# Problem data

ya0 = 0.9

yi0 = 0.1

fa = 163.0 # kmol/h

fa0 = ya0 * fa

ca0 = 9.3 # kmol/m3

T0 = 330 # K

# n-butane = comp 1; i-butane = comp 2; i-Pentane = component 3

theta = np.array([1, 0, yi0/ya0])

cp = np.array([141, 141, 161])

# Initial condition

y0 = [0]

args = (fa0, ca0, T0, theta, cp)

v_final = 5

sol = solve_ivp(adiabatic_pfr, [0, v_final], y0, args=args, dense_output=True)

v = np.linspace(0,v_final, 1000)

x = sol.sol(v)[0]

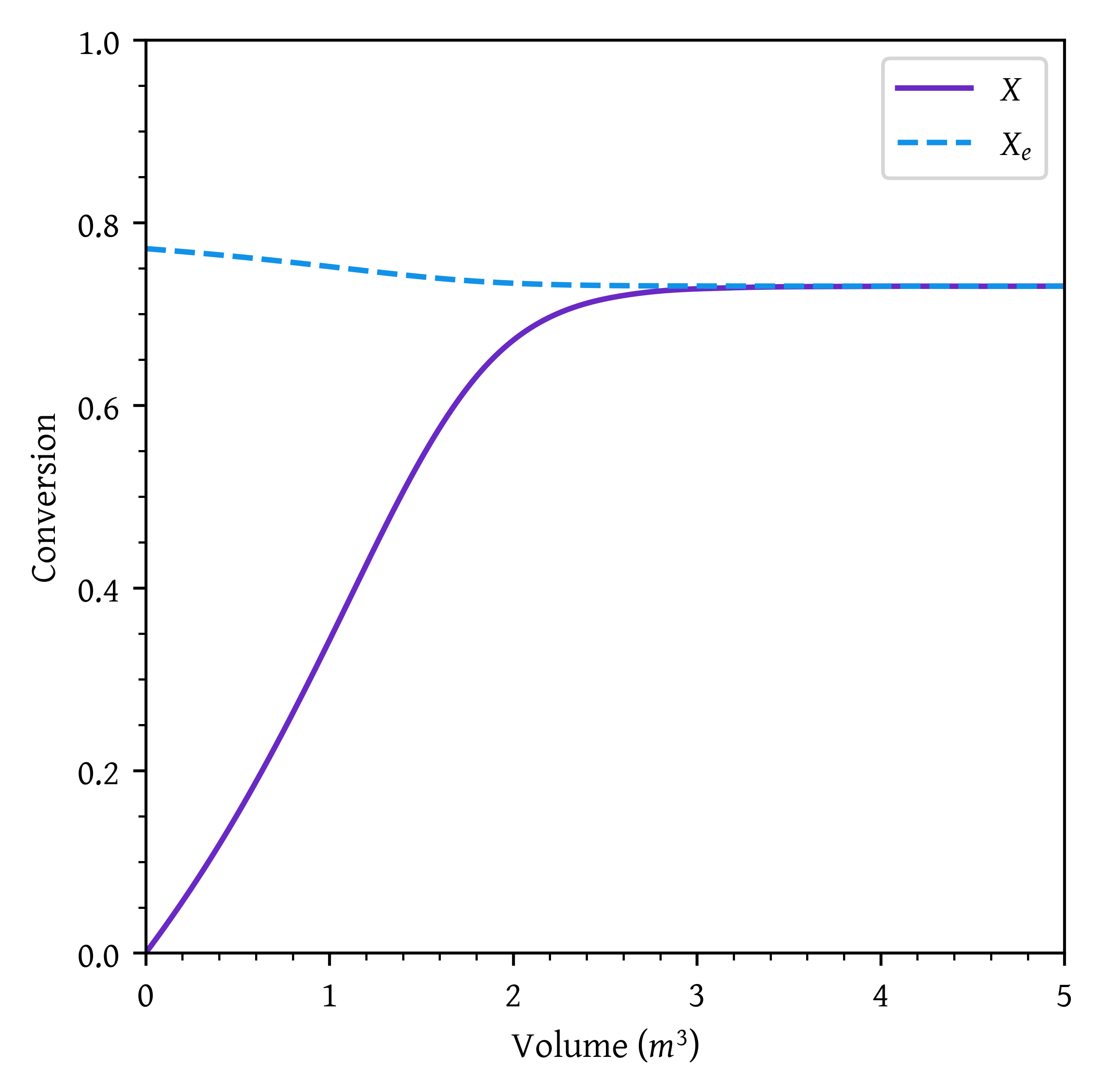

pfr_07 = v[np.argmax(x > 0.7)]PFR volume required to obtain a conversion of 0.7 = 2.24 .

# recalculate other quantities for plotting

sum_cp = np.sum(theta * cp)

T = T0 + (-DELTAHR) * x / sum_cp

Kc = KC0 * np.exp((DELTAHR/R) * (1/T_KC0 - 1/T))

xe = Kc/(1 + Kc)Temperature profile

Conversion profile

CSTR volume

pfr_04 = v[np.argmax(x > 0.4)]

temp_04 = T[np.argmax(x > 0.4)]

kc_04 = Kc[np.argmax(x > 0.4)]

k_04 = K0 * np.exp((E/R) * (1/T_K0 - 1/temp_04))

ca = ca0 * ( 1 - 0.4 )

cb = ca0 * 0.4

rate = k_04 * (ca - cb/kc_04)

cstr_04 = fa0 * 0.4/ ratePFR volume required to obtain a conversion of 0.4 = 1.14 .

CSTR volume required to obtain a conversion of 0.4 = 0.97 .

Adiabatic Equilibrium Temperature

For the elementary liquid-phase reaction

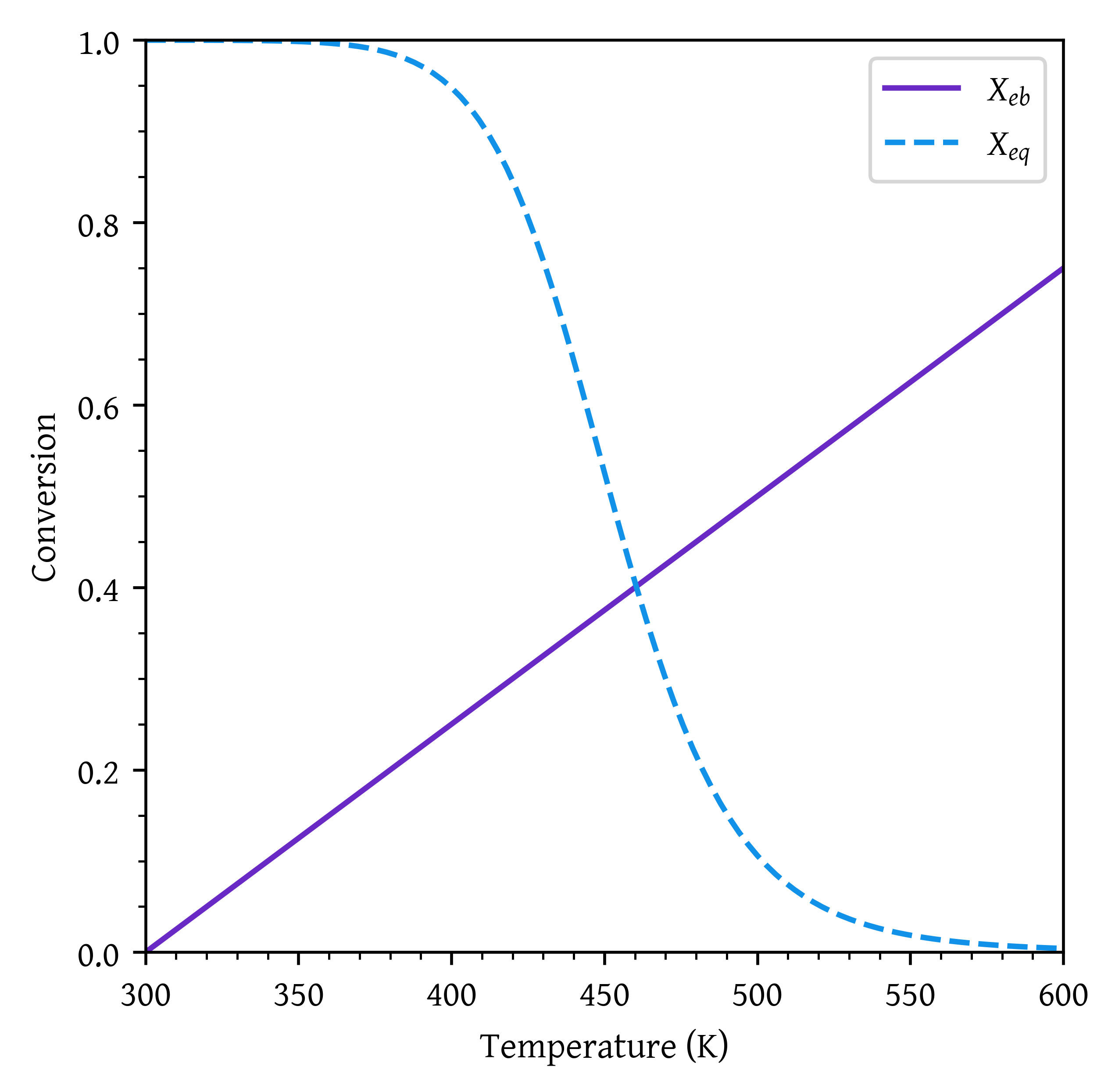

Make a plot of equilibrium conversion as a function of temperature.

Combine the rate law and stoichiometric table to write as a function of , , , and .

Determine the adiabatic equilibrium temperature and conversion when pure A is fed to the reactor at a temperature of 300 K.

What is the CSTR volume to achieve 90% of the adiabatic equilibrium conversion for ?

Additional information:†

at 298 K, with

- Rate law

- Equilibrium

- Stoichiometry

Combining Equation 9, Equation 12, Equation 13, and Equation 14

- Energy balance

From problem statement:

Adiabatic: = 0

No work: = 0

= 141 - 141 = 0

Substituting in Equation 16

import numpy as np

import matplotlib.pyplot as plt

from scipy.integrate import solve_ivp

from scipy.optimize import fsolve

# Constants

HF_A = -40000 # cal/mol

HF_B = -60000 # cal/mol

CP_A = 50 # cal/mol K

CP_B = 50 # cal/mol K

# A <-> B

D_CP = CP_B - CP_A

KE0 = 100000

T_KE0 = 298 # K

K0 = 1e-3 # 1/h

T_K0 = 298 # K

E = 10000 # cal/mol

R = 1.987 # cal/mol K

DELTAHR = HF_B - HF_A

T0 = 300 # K

Ke = lambda T: KE0 * np.exp((DELTAHR/R) * (1/T_KE0 - 1/T))

Xe = lambda T: Ke(T)/(1 + Ke(T))

Xeb = lambda T, T0: CP_A * (T - T0)/(-DELTAHR)

intersect = lambda T: Xe(T) - Xeb(T, T0)

sol = fsolve(intersect, T0)

T_adiab = sol[0]

X_eadiab = Xe( T_adiab )Adiabatic equilibrium temperature = 460.40 K.

Adiabatic equilibrium conversion = 0.40.

T_final = T0 + 300

temperatures = np.linspace(T0, T_final , 100)

conv_eb = Xeb(temperatures, T0)

conv_eq = Xe(temperatures)

plt.plot(temperatures,conv_eb, label="$X_{eb}$")

plt.plot(temperatures,conv_eq, label="$X_{eq}$")

plt.xlabel('Temperature (K)')

plt.ylabel('Conversion')

plt.xlim(T0, T_final)

plt.ylim(0,1)

plt.legend()

plt.show()CSTR Volume

Calculate temperature corresponding to X = 0.9 Xe

Calculate rate at this temperature using Equation 9 and Equation 10.

k = lambda T: K0 * np.exp((E/R) * (1/T_K0 - 1/T))

v_0 = 5 # dm^3/min

x_cstr = 0.9 * X_eadiab

def v_cstr(x, xin, t0, ca0, v_0):

t_cstr = t0 + (x - xin)*(-DELTAHR)/CP_A

rate = k(t_cstr) * ca0 * (1 - (x/Xe(t_cstr)))

v_cstr = v_0 * ca0 * x/rate

return v_cstr,t_cstr

V_cstr,T_cstr = v_cstr(x_cstr,0,T0,1.0,v_0)For a CSTR to achieve a conversion of 90% of (= 0.36), volume required is 17.57 . The CSTR operates at 444.36 .

Interstage Cooling for Highly Exothermic Reactions

What conversion could be achieved in the previous example if two interstage coolers that had the capacity to cool the exit stream to 350 K were available? Also, determine the heat duty of each exchanger for a molar feed rate of A of 40 mol/s. Assume that 95% of the equilibrium conversion is achieved in each reactor. The feed temperature to the first reactor is 300 K.

# Stage 1

fa0 = 40.0 # mol/s

x1 = 0.95 * X_eadiab

v_cstr1, t_cstr1 = v_cstr(x1,0,T0,1.0,v_0)Stage 1: = 0.38. = 25.69 . = 452.38 .

Heat Load:

;

T_ic = 350

qdot1 = fa0 * CP_A * (T_ic - t_cstr1)Stage 1 cooling requirement : = -204.76 .

# Stage 2

# find adiabatic conversion and temperature for second stage

intersect = lambda T: Xe(T) - ( x1 + Xeb(T, T_ic))

sol = fsolve(intersect, T0)

T2_adiab = sol[0]

X2_eadiab = Xe( T2_adiab )

x2 = X2_eadiab * 0.95

v_cstr2, t_cstr2 = v_cstr(x2,x1,T_ic,1.0,v_0)

qdot2 = fa0 * CP_A * (T_ic - t_cstr2)Stage 2: = 0.58. = 442.93 . = 71.24 . = 430.66 .

Stage 2 cooling requirement : = -161.33 .

# Stage 3

# find adiabatic conversion and temperature for second stage

intersect = lambda T: Xe(T) - ( x2 + Xeb(T, T_ic))

sol = fsolve(intersect, T0)

T3_adiab = sol[0]

X3_eadiab = Xe( T3_adiab )

x3 = X3_eadiab * 0.95

v_cstr3, t_cstr3 = v_cstr(x3,x2,T_ic,1.0,v_0)

qdot3 = fa0 * CP_A * (T_ic - t_cstr3)Stage 3: = 0.74. = 428.03 . = 195.40 . = 412.47 .

Stage 3 cooling requirement : = -124.95 .

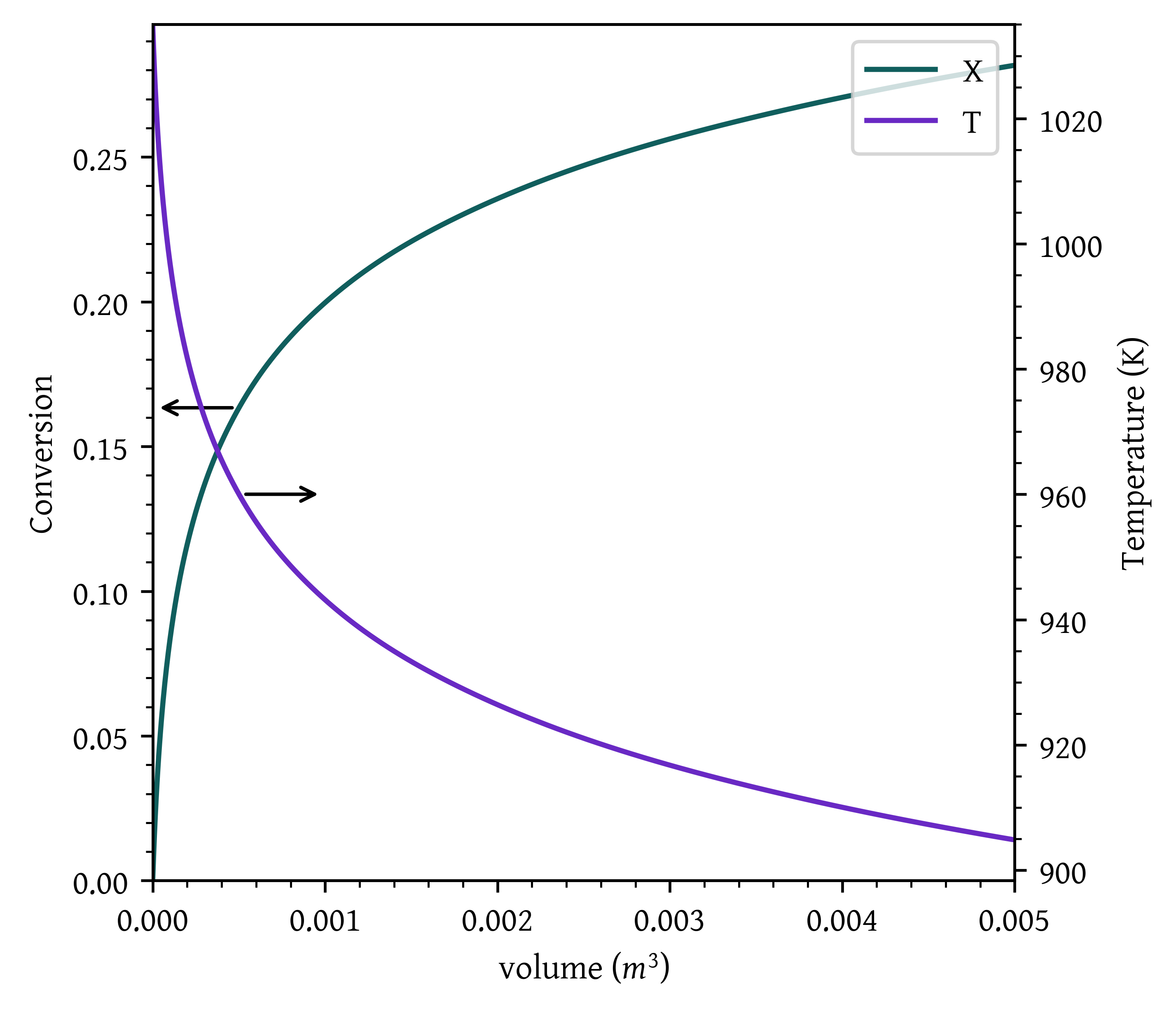

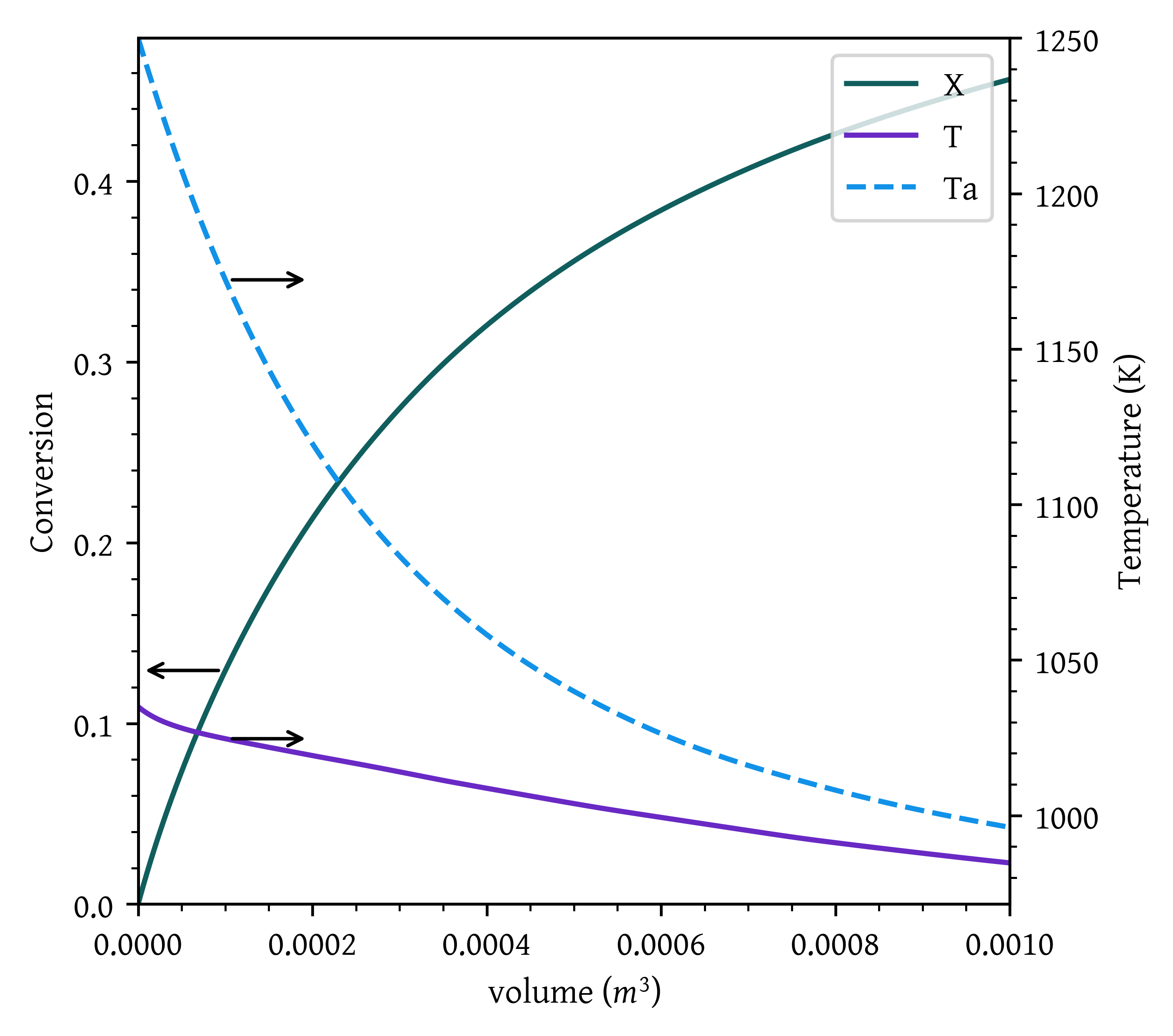

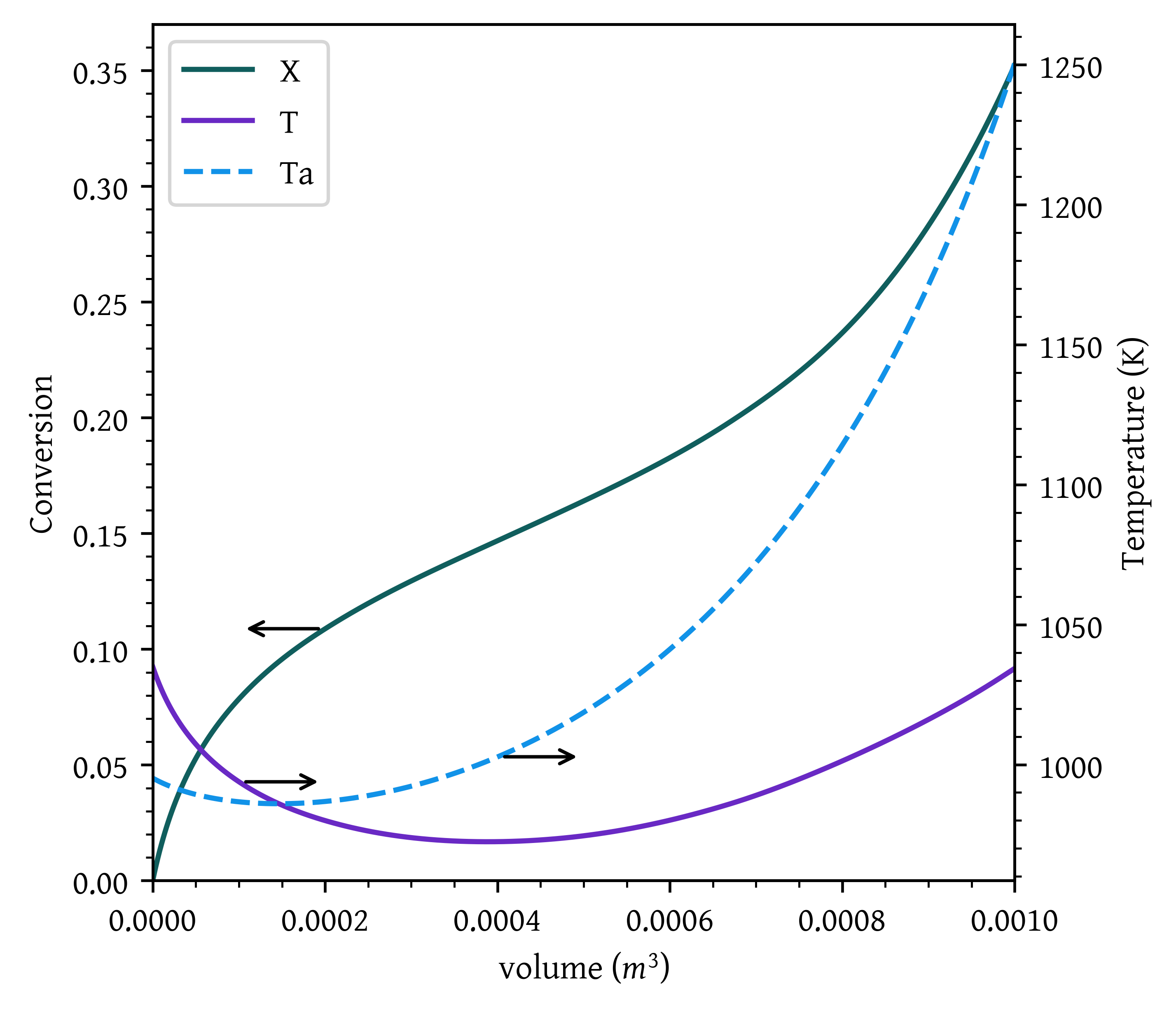

Production of Acetic Anhydride

Jeffreys, in a treatment of the design of an acetic anhydride manufacturing facility, states that one of the key steps is the endothermic vapor-phase cracking of acetone to ketene and methane.

The reaction is as follows:

He states further that this reaction is first-order with respect to acetone and that the specific reaction rate can be expressed by

where is in reciprocal seconds and is in Kelvin. In this design it is desired to feed 7850 kg of acetone per hour to a tubular reactor. The reactor consists of a bank of 1000 one-inch schedule 40 tubes. We shall consider four cases of heat exchanger operation. The inlet temperature and pressure are the same for all cases at 1035 K and 162 kPa (1.6 atm) and the entering heating-fluid temperature available is 1250 K.

A bank of 1000 one-inch, schedule 40 tubes 1.79 m in length corresponds to 1.0 m³ (0.001 m³/tube = 1.0 dm³/tube) and gives 20% conversion. Ketene is unstable and tends to explode, which is a good reason to keep the conversion low. However, the pipe material and schedule size should be checked to learn if they are suitable for these temperatures and pressures. The heat-exchange fluid has a flow rate, , of 0.111 mol/s, with a heat capacity of 34.5 J/mol·K.

The cases are as follows:

- Case 1: The reactor is operated adiabatically.

- Case 2: Constant heat-exchange fluid temperature K.

- Case 3: Co-current heat exchange with K.

- Case 4: Countercurrent heat exchange with K.

Additional information:

- For acetone (A): kJ/mol, J/mol·K

- For ketene (B): kJ/mol, J/mol·K

- For methane (C): kJ/mol, J/mol·K

The overall heat transfer coefficient .

Reaction:

- Mole balance

- Rate law

Stoichiometry

Energy balance

Reactor balance

Heat exchanger

import numpy as np

import matplotlib.pyplot as plt

from scipy.integrate import solve_ivp

# Constants

R = 8.314 # J/mol K

TR = 298 # K

# Components: 1: A(acetone), 2: B(ketene), 3: C(methane)

HF = np.array ([-216.67, -61.09, -74.81])*1000 # J/mol

CP = np.array ([163.0, 83.0, 71.0]) # J/mol K

MW = np.array ([58.0, 42.0, 20.0]) # g/mol

k = lambda t: np.exp( 34.34 - 34222/t )

# k = lambda t: 3.58 * np.exp( 34222 * (1/1035 - 1/t))

def pfr (v, x, *args):

X, T, Ta = x

(fa0, ca0, T0, epsilon, delta_hr_tr, delta_cp, theta, UA, mc, cpc) = args

ca = ca0 * (( 1 - X ) / ( 1 + epsilon * X )) * (T0/T)

rate = k(T) * ca # -r_A

delta_h = delta_hr_tr + delta_cp * (T - TR)

dxdv = rate/fa0

dtdv = (UA * ( Ta - T ) + (-rate * delta_h))/( fa0 * ( np.sum(theta * CP) + X * delta_cp) )

dtadv = UA * ( T - Ta )/ (mc * cpc)

return [dxdv, dtdv, dtadv]

# Data

nu = np.array ([-1.0, 1.0, 1.0]) # stoichiometric coefficients

f0 = 7850 # kg/h

T0 = 1035.0 # K

P0 = 162.0e3 # Pa

n_tubes = 1000

d_tube = 26.64e-3 # 1" schedule 40 pipe inner diameter mm

Ta0 = 1250 # K

a = 4/d_tube

U = 110.0 # J/s m^3 K

UA = U * a

mc = 0.111 # mol/s

cpc = 34.5 # J/mol K

# inlet mole fraction

y0 = np.array ([1.0, 0.0, 0.0])

theta = np.array([1.0, 0.0, 0.0])

fa0 = (f0 / ( y0[0] * MW[0])) / n_tubes # kmol/h

fa0 = fa0 * (1000/3600) # mol/s

pa0 = y0[0] * P0

ca0 = pa0/(R * T0)

v_0 = fa0/ca0

ya0 = y0[0]

# Heat of reaction at 298K

delta_hr_tr = np.sum(HF * nu)

delta_cp = np.sum(CP * nu)

epsilon = ya0 * np.sum(nu)| Parameter values | ||

|---|---|---|

| = 80770.00 | = -9.00 | = 1035.00 K |

| = 3.76e-02 mol/s | = 18.83 | = 298.00 K |

| = 163.00 | = 16516.52 | = 0.11 |

| = 34.50 | = 0.001 |

args = (fa0, ca0, T0, epsilon, delta_hr_tr, delta_cp, theta, 0, mc, cpc)

initial_conditions = np.array([0, T0, Ta0])

v_final = 0.005

sol = solve_ivp(pfr, [0, v_final], initial_conditions, args=args, dense_output=True)

v = np.linspace(0,v_final, 1000)

x = sol.sol(v)[0]

T = sol.sol(v)[1]

Ta = sol.sol(v)[2]

fig, ax1 = plt.subplots()

# Plot x on the original y-axis

plt_x = ax1.plot(v, x, color='#105e5d', label='X')

ax1.set_xlabel('volume ($m^3$)')

ax1.set_ylabel('Conversion')

ax1.set_xlim(0,v[-1])

ax1.set_ylim(0,)

# Create a second y-axis for T and Ta

ax2 = ax1.twinx()

plt_t = ax2.plot(v, T, label='T')

# plt_ta = ax2.plot(v, Ta, label='Ta')

ax2.set_ylabel('Temperature (K)')

ax2.set_xlim(0,v[-1])

ax2.set_ylim(top=T0)

arrow_properties = dict(arrowstyle="<-,head_length=0.7,head_width=0.25",

color="black")

ax1.annotate('', xy=(v[100],x[100]), xytext=(v[0], x[100]),arrowprops=dict(arrowstyle="<-"))

ax2.annotate('', xy=(v[100],T[100]), xytext=(v[200], T[100]),arrowprops=dict(arrowstyle="<-"))

# fig.tight_layout()

handles, labels = [], []

for ax in [ax1, ax2]:

for handle, label in zip(*ax.get_legend_handles_labels()):

handles.append(handle)

labels.append(label)

plt.legend(handles, labels)

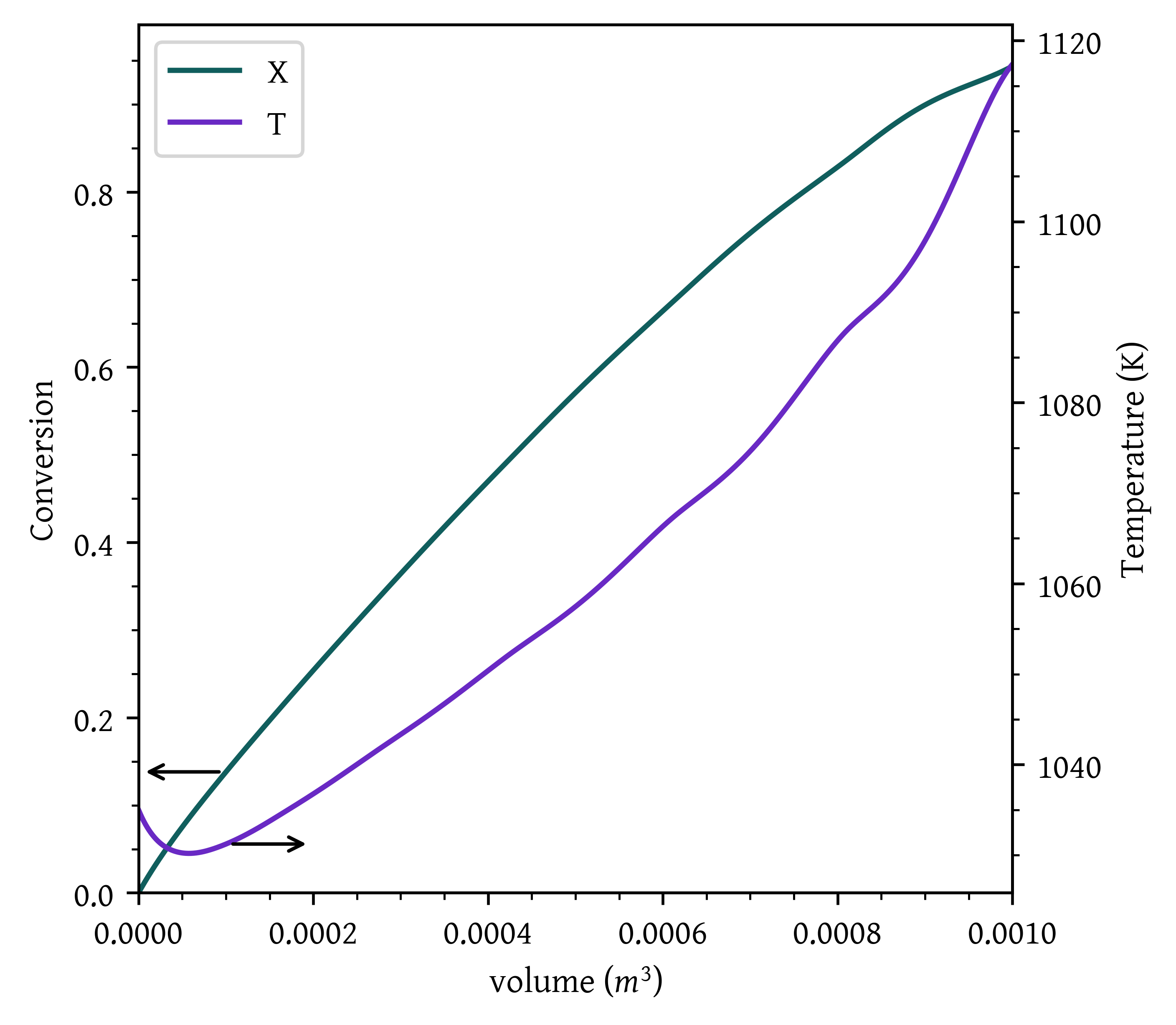

plt.show()def pfr_const_heatex_fluid_T (v, x, *args):

X, T, Ta = x

(fa0, ca0, T0, epsilon, delta_hr_tr, delta_cp, theta, UA, mc, cpc) = args

ca = ca0 * (( 1 - X ) / ( 1 + epsilon * X )) * (T0/T)

rate = k(T) * ca # -r_A

delta_h = delta_hr_tr + delta_cp * (T - TR)

dxdv = rate/fa0

dtdv = (UA * ( Ta - T ) + (-rate * delta_h))/( fa0 * ( np.sum(theta * CP) + X * delta_cp) )

dtadv = 0.0

return [dxdv, dtdv, dtadv]

args = (fa0, ca0, T0, epsilon, delta_hr_tr, delta_cp, theta, UA, mc, cpc)

initial_conditions = np.array([0, T0, Ta0])

v_final = 0.001

sol = solve_ivp(pfr_const_heatex_fluid_T, [0, v_final], initial_conditions, args=args, dense_output=True)

v = np.linspace(0,v_final, 1000)

x = sol.sol(v)[0]

T = sol.sol(v)[1]

Ta = sol.sol(v)[2]

fig, ax1 = plt.subplots()

# Plot x on the original y-axis

plt_x = ax1.plot(v, x, color='#105e5d', label='X')

ax1.set_xlabel('volume ($m^3$)')

ax1.set_ylabel('Conversion')

ax1.set_xlim(0,v[-1])

ax1.set_ylim(0,)

# Create a second y-axis for T and Ta

ax2 = ax1.twinx()

plt_t = ax2.plot(v, T, label='T')

# plt_ta = ax2.plot(v, Ta, label='Ta')

ax2.set_ylabel('Temperature (K)')

ax2.set_xlim(0,v[-1])

arrow_properties = dict(arrowstyle="<-,head_length=0.7,head_width=0.25",

color="black")

ax1.annotate('', xy=(v[100],x[100]), xytext=(v[0], x[100]),arrowprops=dict(arrowstyle="<-"))

ax2.annotate('', xy=(v[100],T[100]), xytext=(v[200], T[100]),arrowprops=dict(arrowstyle="<-"))

# fig.tight_layout()

handles, labels = [], []

for ax in [ax1, ax2]:

for handle, label in zip(*ax.get_legend_handles_labels()):

handles.append(handle)

labels.append(label)

plt.legend(handles, labels)

plt.show()args = (fa0, ca0, T0, epsilon, delta_hr_tr, delta_cp, theta, UA, mc, cpc)

initial_conditions = np.array([0, T0, Ta0])

v_final = 0.001

sol = solve_ivp(pfr, [0, v_final], initial_conditions, args=args, dense_output=True)

v = np.linspace(0,v_final, 1000)

x = sol.sol(v)[0]

T = sol.sol(v)[1]

Ta = sol.sol(v)[2]

fig, ax1 = plt.subplots()

# Plot x on the original y-axis

plt_x = ax1.plot(v, x, color='#105e5d', label='X')

ax1.set_xlabel('volume ($m^3$)')

ax1.set_ylabel('Conversion')

ax1.set_xlim(0,v[-1])

ax1.set_ylim(0,)

# Create a second y-axis for T and Ta

ax2 = ax1.twinx()

plt_t = ax2.plot(v, T, label='T')

plt_ta = ax2.plot(v, Ta, label='Ta')

ax2.set_ylabel('Temperature (K)')

ax2.set_xlim(0,v[-1])

ax2.set_ylim(top=Ta0)

arrow_properties = dict(arrowstyle="<-,head_length=0.7,head_width=0.25",

color="black")

ax1.annotate('', xy=(v[100],x[100]), xytext=(v[0], x[100]),arrowprops=dict(arrowstyle="<-"))

ax2.annotate('', xy=(v[100],T[100]), xytext=(v[200], T[100]),arrowprops=dict(arrowstyle="<-"))

ax2.annotate('', xy=(v[100],Ta[100]), xytext=(v[200], Ta[100]),arrowprops=dict(arrowstyle="<-"))

# fig.tight_layout()

handles, labels = [], []

for ax in [ax1, ax2]:

for handle, label in zip(*ax.get_legend_handles_labels()):

handles.append(handle)

labels.append(label)

plt.legend(handles, labels)

plt.show()def pfr_countercurrent_exchange (v, x, *args):

X, T, Ta = x

(fa0, ca0, T0, epsilon, delta_hr_tr, delta_cp, theta, UA, mc, cpc) = args

ca = ca0 * (( 1 - X ) / ( 1 + epsilon * X )) * (T0/T)

rate = k(T) * ca # -r_A

delta_h = delta_hr_tr + delta_cp * (T - TR)

dxdv = rate/fa0

dtdv = (UA * ( Ta - T ) + (-rate * delta_h))/( fa0 * ( np.sum(theta * CP) + X * delta_cp) )

dtadv = - UA * ( T - Ta )/ (mc * cpc)

return [dxdv, dtdv, dtadv]

v_final = 0.001

# This temperature needs to be guessed for Ta to be 1250 at V = V_final

Ta0 = 995.15

args = (fa0, ca0, T0, epsilon, delta_hr_tr, delta_cp, theta, UA, mc, cpc)

initial_conditions = np.array([0, T0, Ta0])

sol = solve_ivp(pfr_countercurrent_exchange, [0, v_final], initial_conditions, args=args, dense_output=True)

v = np.linspace(0,v_final, 1000)

x = sol.sol(v)[0]

T = sol.sol(v)[1]

Ta = sol.sol(v)[2]

fig, ax1 = plt.subplots()

# Plot x on the original y-axis

plt_x = ax1.plot(v, x, color='#105e5d', label='X')

ax1.set_xlabel('volume ($m^3$)')

ax1.set_ylabel('Conversion')

ax1.set_xlim(0,v[-1])

ax1.set_ylim(0,)

# Create a second y-axis for T and Ta

ax2 = ax1.twinx()

plt_t = ax2.plot(v, T, label='T')

plt_ta = ax2.plot(v, Ta, label='Ta')

ax2.set_ylabel('Temperature (K)')

ax2.set_xlim(0,v[-1])

arrow_properties = dict(arrowstyle="<-,head_length=0.7,head_width=0.25",

color="black")

ax1.annotate('', xy=(v[200],x[200]), xytext=(v[100], x[200]),arrowprops=dict(arrowstyle="<-"))

ax2.annotate('', xy=(v[100],T[100]), xytext=(v[200], T[100]),arrowprops=dict(arrowstyle="<-"))

ax2.annotate('', xy=(v[400],Ta[400]), xytext=(v[500], Ta[400]),arrowprops=dict(arrowstyle="<-"))

# fig.tight_layout()

handles, labels = [], []

for ax in [ax1, ax2]:

for handle, label in zip(*ax.get_legend_handles_labels()):

handles.append(handle)

labels.append(label)

plt.legend(handles, labels)

plt.show()References

Citation

@online{utikar2024,

author = {Utikar, Ranjeet},

title = {In Class Activity: {Non-isothermal} Reactor Design},

date = {2024-04-01},

url = {https://cre.smilelab.dev/content/notes/07-non-isothermal-reactor-design/in-class-activities.html},

langid = {en}

}