In class activity: Conversion and Reactor sizing

Lecture notes for chemical reaction engineering

Design equations in terms of conversion

Derive design equation in terms of conversion for a CSTR

Derive design equation in terms of conversion for a PFR

CSTR sizing

Using the data in Table 1, calculate for , and

PFR sizing

Using the data in Table 2, calculate for , and

An Adiabatic Liquid-Phase Isomerization

The isomerization of butane

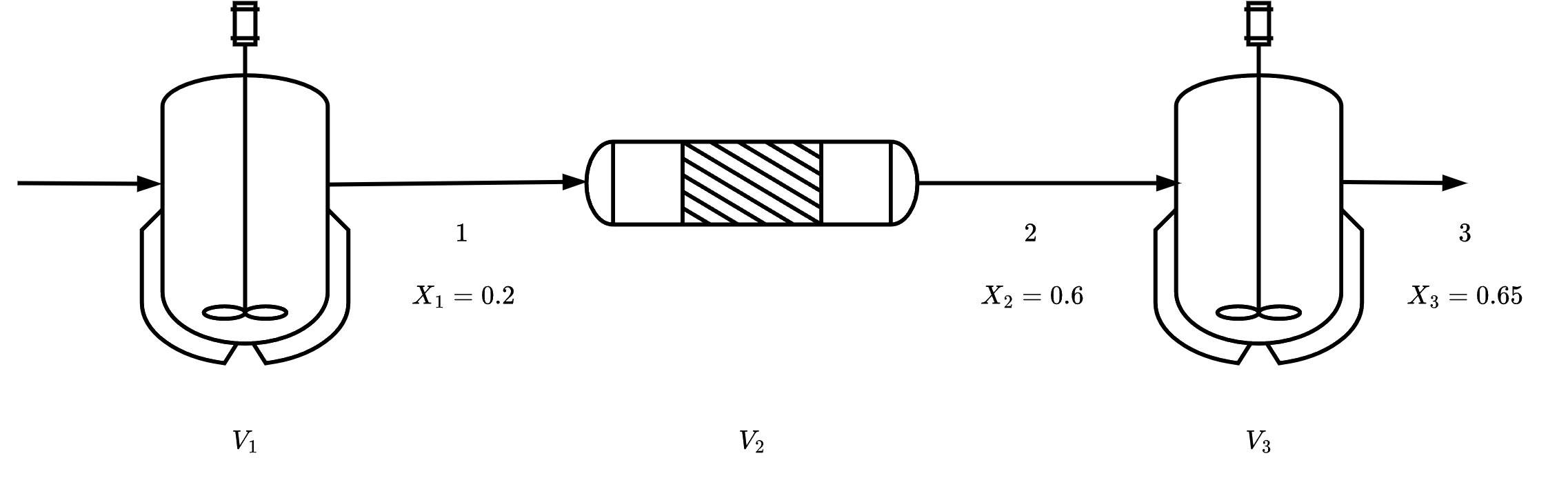

was carried out adiabatically in the liquid phase. The data for this reversible reaction are given in Table 3. The reactor scheme shown below in Figure 1. Calculate the volume of each of the reactors for an entering molar flow rate of n-butane of 50 kmol/hr.

Batch reactor sizing

Discuss how you can use Levenspeil plots to design batch reactors.

We are planning to operate a batch reactor for converting A into R. This is a liquid phase reaction with stoichiometry . How long must we react each batch for concentration to drop from = 1.3 mol/l to = 0.30 mol/l? The data of rate of reaction v/s concentration of A is given in Table 4.

Citation

@online{utikar2024,

author = {Utikar, Ranjeet},

title = {In Class Activity: {Conversion} and {Reactor} Sizing},

date = {2024-03-03},

url = {https://cre.smilelab.dev/content/notes/02-conversion-and-reactor-sizing/in-class-activities.html},

langid = {en}

}