External and internal diffusion effects

Chemical Reaction Engineering

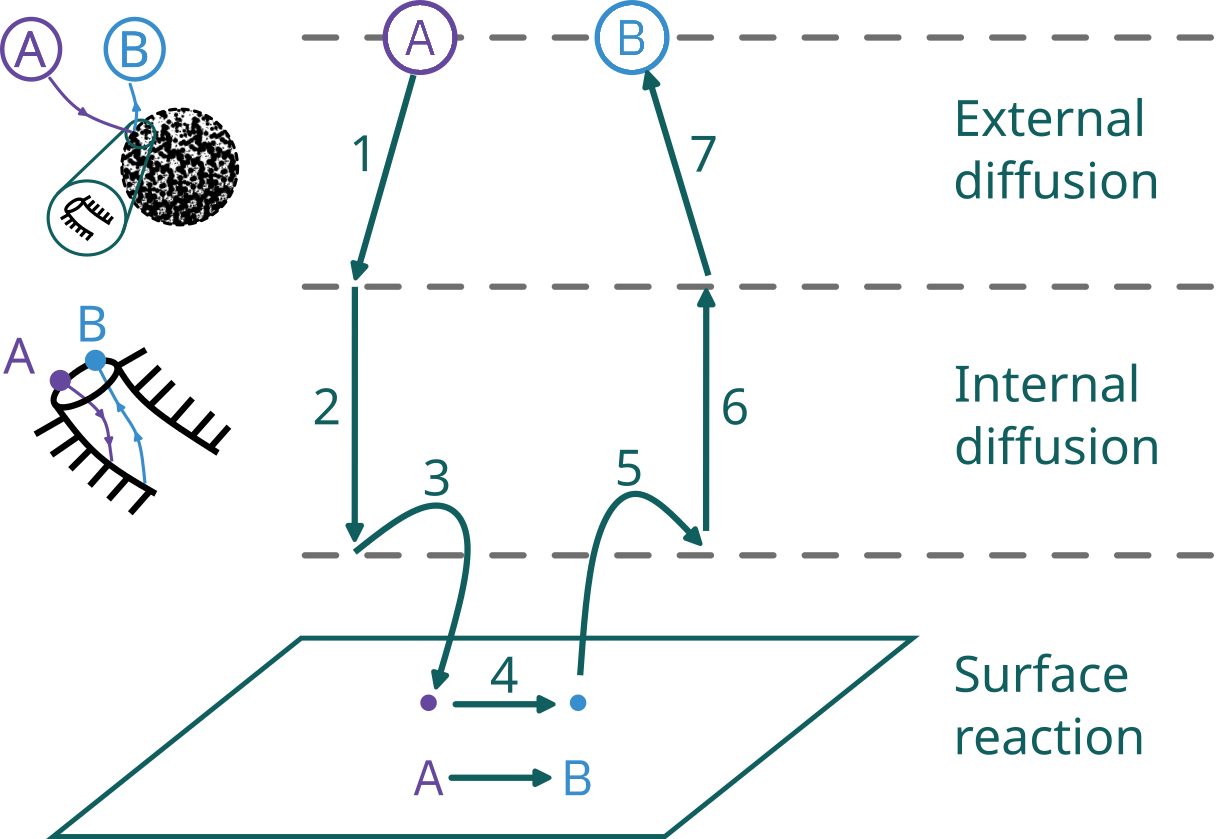

Steps in a heterogeneous catalytic reaction

Diffusion effects

Industrial reactions at high temperature

- Limited by the rate of mass transfer between bulk fluid and the catalytic surface.

Mass transfer

- Any process in which diffusion plays a role.

- Rate laws cannot be applied directly.

- Need to consider fluid velocity and fluid properties while writing molar balances.

External mass transfer

External mass transfer

Internal mass transfer

Diffusion: definitions

Molar flux with no diffusion

WAz=ACCAυ=ACFAz

m2⋅smolm3mol⋅sm3⋅m21

- FAz: Uniform at a given cross section (plug flow assumption)

Diffusion

- Spontaneous intermingling or mixing of atoms or molecules by random thermal motion.

- Gives rise to the motion of species relative to the motion of the mixture.

- From regions of high concentration to regions of low concentration in the absence of other gradients.

- Diffusion results in a molar flux of the species (A), WA (moles/area time), in the direction of the concentration gradient.

WA=iWAx+jWAy+kWAz[Rectangular coordinates]

⇒ Need to develop mole balance that incorporates both diffusion and reaction.

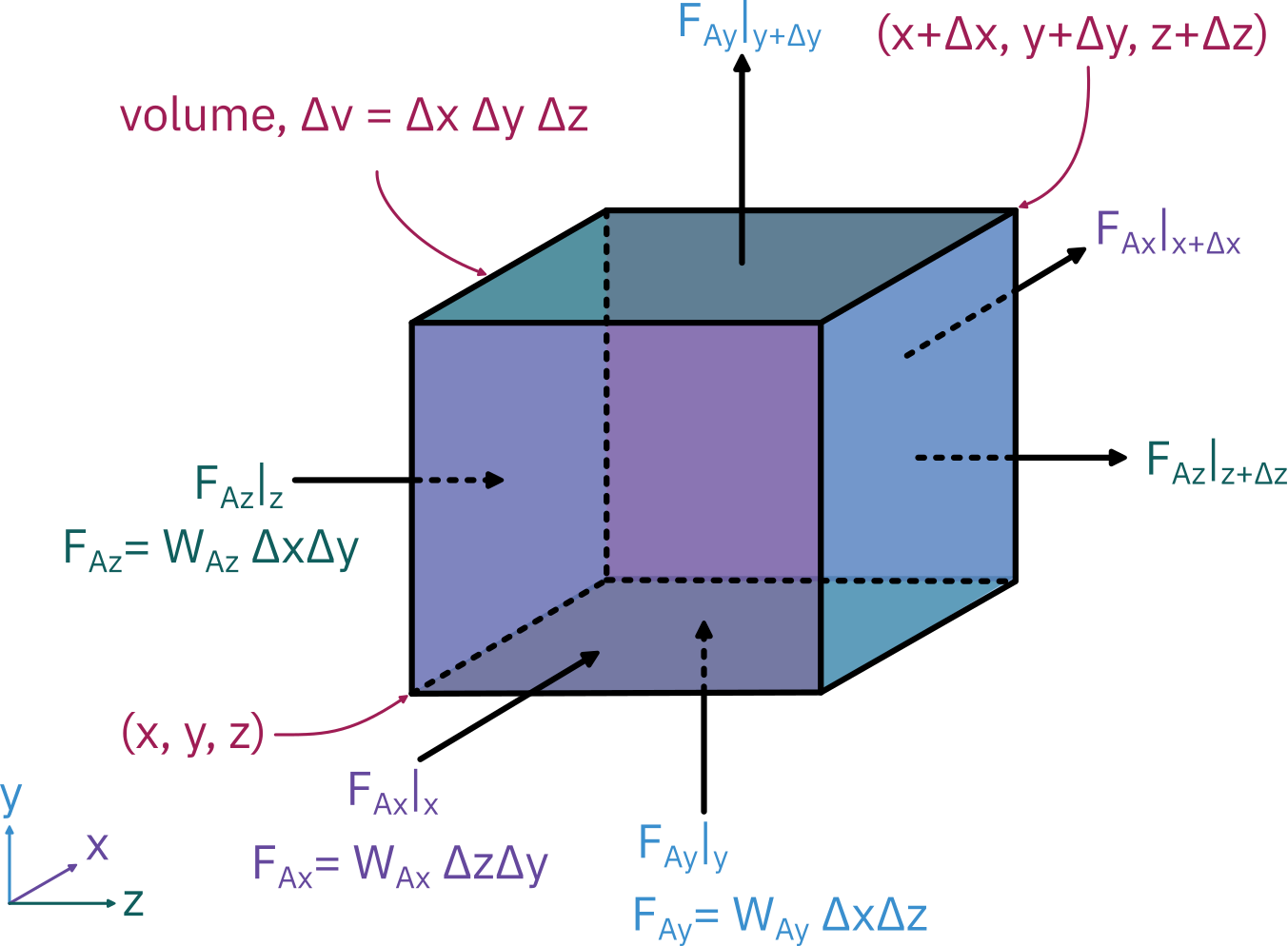

Mole balance in rectangular coordinates

Mole balance in rectangular coordinates

+++=[molar flow rate in]z−[molar flow rate in]y−[molar flow rate in]x−[rate of generation][rate of accumulation][molar flow rate out]z+Δz[molar flow rate out]y+Δy[molar flow rate out]x+Δx

ΔxΔyWAzz+ΔzΔyWAxx−−ΔxΔyWAzz+ΔzΔzΔyWAxx+Δx+ΔxΔzWAyy+rAΔxΔyΔz−=ΔxΔzWAyy+ΔyΔxΔyΔz∂t∂CA

Differential Form:

Dividing by ΔxΔyΔz and taking the limit as they go to zero:

∂x∂WAx+∂y∂WAy+∂z∂WAz+rA=∂t∂CA

Molar Flux

- WA: Total molar flux of species A

- JA: Molecular diffusion flux relative to bulk motion of fluid due to concentration gradient

- BA: Flux resulting from bulk motion of fluid

WA=JA+BA

- BA: =yA(∑Wi)

- ∑Wi: Total flux of all molecules

- yA: mole fraction of A

- For A→B (two-component system):

WA=JA+yA(WA+WB)=JA+CAU

Fick’s law

Describes how molar diffusive flux is related to the concentration gradient.

Fourier’s Law (thermal conduction)

q=−kt∇T;kt:thermal conductivity

∇=i∂x∂+j∂y∂+k∂z∂

For Mass Transfer: Fick’s Law

JA=−DAB∇CA

- DAB: Diffusivity of A in B (m2/s)

WA=−DAB∇CA+CAU

In One Dimension

WAz=−DABdzdCA+CAUz

Evaluating Molar Flux

A diffusing in B

WA=−DAB∇CA+yA(WA+WB)

Equimolar Counter Diffusion (EMCD)

WA=−WBWA=JA=−DAB∇CA

Species A Diffusing Through Stagnant Species B ( WB=0;WA=JA+yAWA )

- Solid boundary with adjacent stagnant fluid layer

WA=1−yAJA=−1−yADAB∇CA;WA=−DABC∇ln(1−yA)

Bulk Flow of A≫ Molecular Diffusion (plug flow model)

WA=BA=yA(WA+WB)=CAU

Evaluating Molar Flux

Small Bulk Flow JA≫BA

WA=−DAB∇CA=JA

Knudsen Diffusion

Occurs in porous catalyst where diffusing molecule collides more often with catalyst walls/pore walls than with each other.

WA=JA=−Dk∇CA

Dk: Knudsen diffusivity

Diffusion and convective transport: FAz=WAzAC

- FAz: molar flow rate of A in z direction; WAz: molar flux in z; AC: cross-sectional area normal to flow

WAz=−DAzdzdCA+CAUz

FAz=WAzAC=[−DAzdzdCA+CAUz]AC

- Similar expressions for FAy and FAx.

Mole balance in rectangular coordinates

- Substituting expressions for FAz, FAy, and FAx in mole balance

DAB[∂x2∂2CA+∂y2∂2CA+∂z2∂2CA]−ux∂x∂CA−uy∂y∂CA−uz∂z∂CA+rA=∂t∂CA

- In one dimension:

DAB∂z2∂2CA−Uz∂z∂CA+rA=∂t∂CA

Boundary conditions

Concentration at boundary: @z=0→CA=CA0;@z=L→dzdCA=0

Specify flux at the boundary

No mass transfer WA=0

Molar flux at surface = rate of reaction at surface

WA∣surface=−r′′∣surface

Molar flux to boundary = convective transport across boundary layer

WA∣boundary=kc(CAb−CAs)

Temperature and pressure dependence of DAB

| Phase | cm2/s | m2/s | Temperature and pressure dependences |

|---|---|---|---|

| Gas | |||

| - Bulk | 10−1 | 10−5 | DAB(T2,P2)=DAB(T1,P1)P2P1(T1T2)1.75 |

| - Knudsen | 10−2 | 10−6 | DAB(T2)=DA(T1)(T1T2)1/2 |

| Liquid | 10−5 | 10−9 | DAB(T2)=DAB(T1)μ2μ1(T1T2) |

| Solid | 10−9 | 10−13 | DAB(T2)=DAB(T1)exp[RED(T1T2T2−T1)] |

- μ1,μ2 are the liquid viscosities at temperatures T1 and T2 respectively.

- ED is the diffusion activation energy.

- Knudsen, liquid, and solid DAB are independent of P.

Modeling diffusion with chemical reaction

- Diffusion of species through stagnant film in which no reaction takes place

- A reacts instantaneously upon reaching the surface CAs≈0

- Rate of diffusion through stagnant film = rate of reaction on the surface

Steps:

- Perform differential mole balance → Equation for WAz

- Replace WAz by appropriate expression for concentration gradient

- State boundary conditions

- Solve for concentration profile

- Solve for molar flux

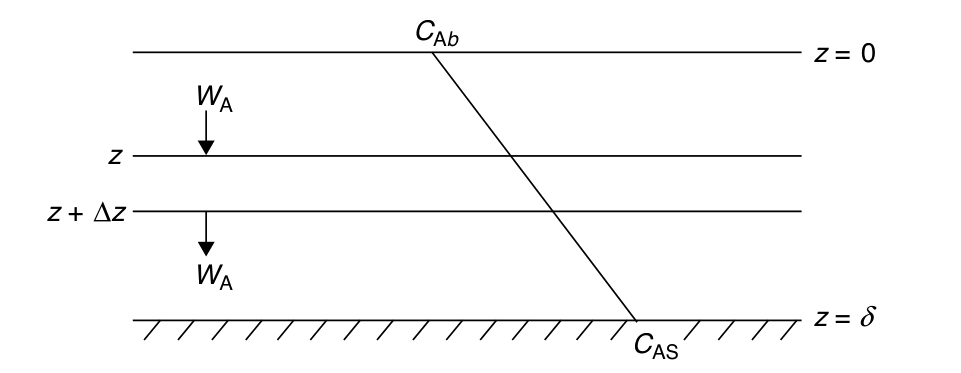

Diffusion through a stagnant film

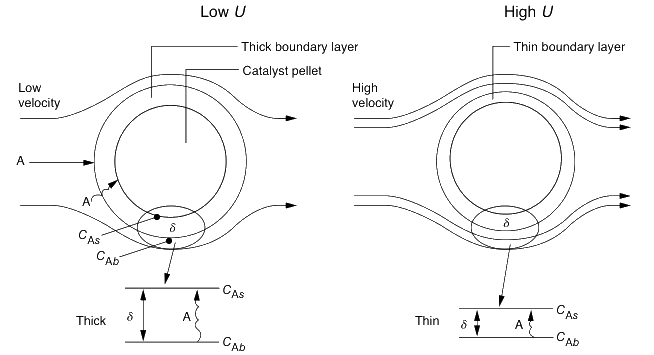

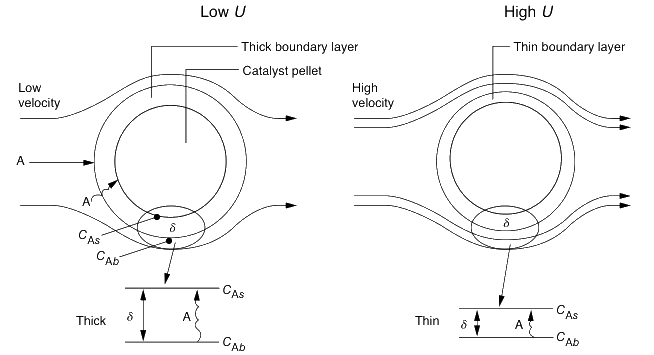

Flow Past a Single Catalytic Pellet

- Reaction takes place only on external catalyst surface and not in fluid surrounding it.

Hydrodynamic Boundary Layer: Distance from solid object to where the fluid velocity is 99% of the bulk velocity U0.

Mass Transfer Boundary Layer: Distance at which concentration of diffusing species is 99% of the bulk concentration.

- We cannot measure δ.

Diffusion through a stagnant film

- Assumption:

- Fluid layer next to solid as stagnant film (hypothetical) of thickness δ.

- All the resistance to mass transfer is within the film.

- Properties at the outer edge of the film are identical to those of bulk fluid.

- For film thickness ≪ radius of pellet:

- Curvature effects can be neglected

- Problem reduces to 1D diffusion.

InWAzz−−OutWAzz+Δz++Generation0==Accumulation0

Diffusion through a stagnant film

Dividing by Δz and taking the limit as Δz→0 dzdWAz=0

For diffusion through stagnant film at dilute concentrations,

JA≫yA(WA+WB)

WAz=−DABdzdCA(also for EMCD)

- Therefore, mole balance becomes

dz2d2CA=0

- Boundary Conditions (BCs)

- At z=0, CA=CAs; At z=δ, CA=CAb

Diffusion through a stagnant film

Integrating twice CA=k1z+k2⟹CAs=k2and(δCAb−CAs)=k1

Substituting BCs

CA=CAs+(CAb−CAs)δz

- Surface Flux

WAzδ=−DABdzdCAδ

WAz=δDAB[CAb−CAs]

- At steady state: Flux of A to the surface=Rate of reaction of A on surface

The mass transfer coefficient

kc=δDAB

- Average molar flux from the bulk fluid to the surface

WAz=kc(CAb−CAs)

WAz=Flux=ResistanceDriving force=(kc1)CAb−CAs

The mass transfer coefficient is found by experimentation

Correlations analogous to what one finds for a heat transfer coefficient.

Sh=2+0.6Re1/2Sc1/3 Fro¨ssling correlation

Sh=DABkcL;Sc=DABν=ρDABμ;Re=νUL=μULρ

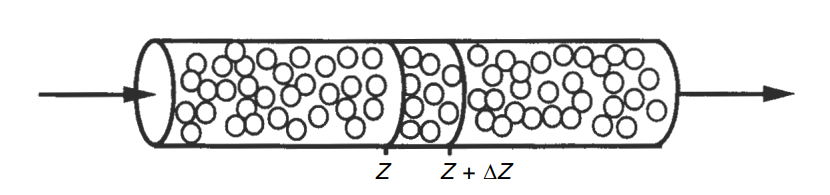

Mass transfer–limited reactions in packed beds

[Molar rate in]−[Molar rate out]+[Molar rate of generation]=[Molar rate of accumulation]

- In one dimension at steady state

FAzz−FAzz+Δz+rA′′c(AcΔz)=0

- Dividing by AcΔz and taking the limit as Δz→0

−Ac1(dzdFAz)+rA′′c=0

Mass transfer–limited reactions in packed beds

- Express FAz and r′′ in terms of concentration

FAz=AcWAz=(JAz+BAz)Ac

In almost all situations involving flow in packed-bed reactors, the amount of material transported by diffusion or dispersion in the axial direction is negligible compared with that transported by convection (i.e., bulk flow)

Neglecting dispersion as JAz≪BAz

FAz=AcWAz=AcBAz=UcAc

−dzd(CU)+rA′′c=0

For constant superficial velocity

−UdzdC+rA′′c=0

Mass transfer–limited reactions in packed beds

The boundary condition at the external surface is

−rA′′=WAr=kc(CA−CAs)

−UdzdC−kcac(CA−CAs)=0

−UdzdC=kcac(CA−CAs)

In most mass transfer-limited reactions, the surface concentration is negligible with respect to the bulk concentration (CA≫CAs)

−UdzdC=kcacCA

At z=0,CA=CA0

CA0CA=exp(−Ukcacz);ln1−X1=UkcacL

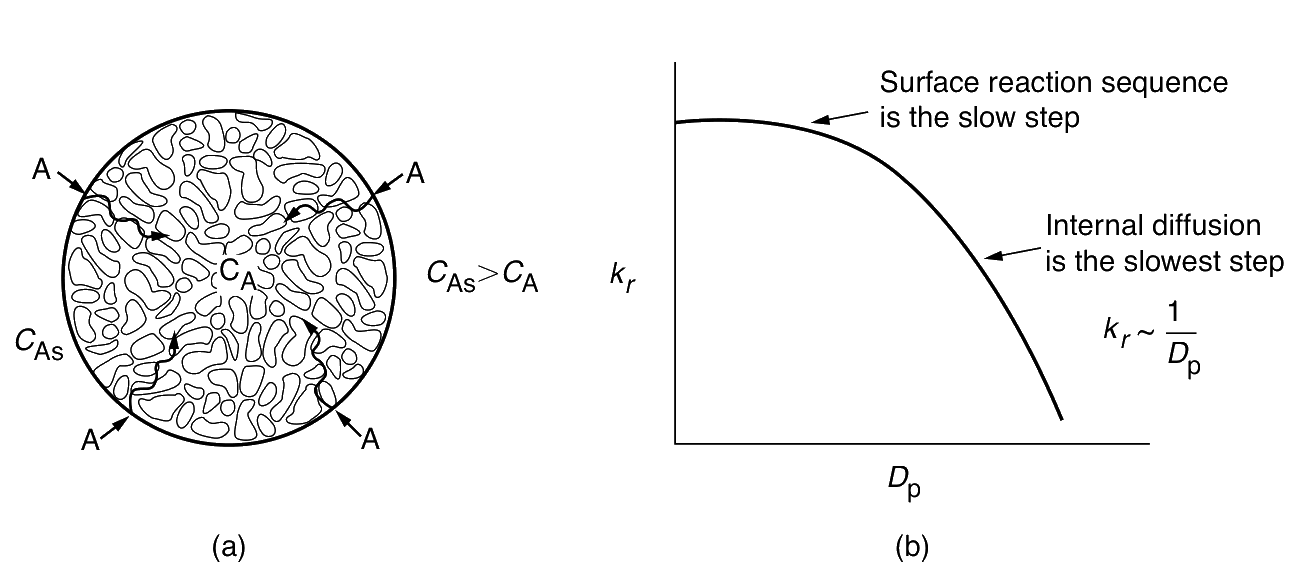

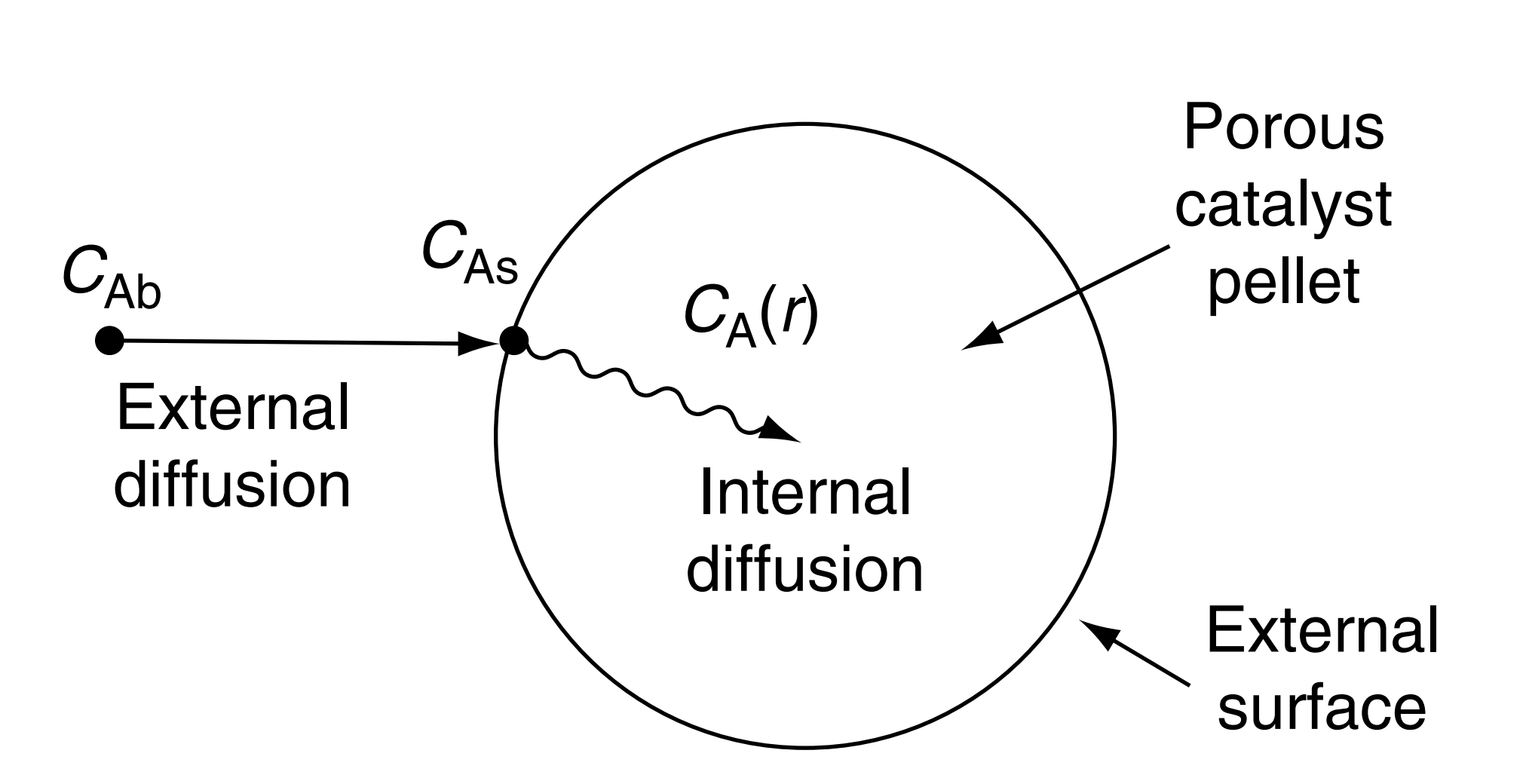

Diffusion and reactions in homogeneous systems

- When reactants must diffuse inside a catalyst pellet in order to react

- The concentration at the pore mouth must be higher than that inside the pore.

- Entire catalyst surface is not accessible to the same concentration

- The rate of reaction to vary throughout the pellet.

Diffusion and Reaction in Homogeneous Systems

- Mole balance on species A for 1D diffusion at steady state

−dzdWAz+rA=0

WAz=−DABdzdCA

DABdz2d2CA+rA=0

Applications

- Medicine

- Cancer treatment using drug-laced particulates

- Tissue engineering

Effective diffusivity

De=τ~DABϕpσc;WAz=−DedzdCA

The effective diffusivity accounts for the fact that:

- Not all of the area normal to the direction of the flux is available (i.e., the area occupied by solids) for the molecules to diffuse, (porosity, ϕp)

- The paths are tortuous (tortuosity, τ~)

- The pores are of varying cross-sectional areas (Constriction factor, σc)

Diffusion and reactions in spherical catalyst pellets

Consider irreversible isomerization reaction AB

The reaction occurs on the surface of pore walls within a spherical pellet of radius R.

Assumptions

- Steady state; spherical coordinates

- Constant pressure and temperature conditions

- Steady state mole balance on a spherical shell r→r+Δr

(In at r)(WAr4πr2∣r)−−(Out at r+Δr)(WAr4πr2∣r+Δr)++(Generation within Δr)(rA′ρc4πrm2Δr)==00

- Dividing by −4πΔr and taking limit as Δr→0

drd(WArr2)−rA′ρcr2=0

Diffusion and reactions in spherical catalyst pellets

WAr=−DedrdCA

dr−De(dCA/dr)r2−r2ρcrA′=0

Reaction rate {rA′=knCAn}

- per unit surface area −rA′′

- per unit mass of catalyst −rA′=Sa(−rA′′)

- per unit volume −rA=ρc(−rA′)=ρcSa(−rA′′)

dr2d2CA+r2(drdCA)−DeknCAn=0

Boundary conditions

- At the center of pellet: at r=0, CA is finite

- At the external surface: at r=R, CA=CAs

Diffusion and reactions in spherical catalyst pellets

Dimensionless form

ψ=CAsCA;λ=Rr

Boundary conditions

- At λ=0, ψ is finite

- At λ=1, ψ=1

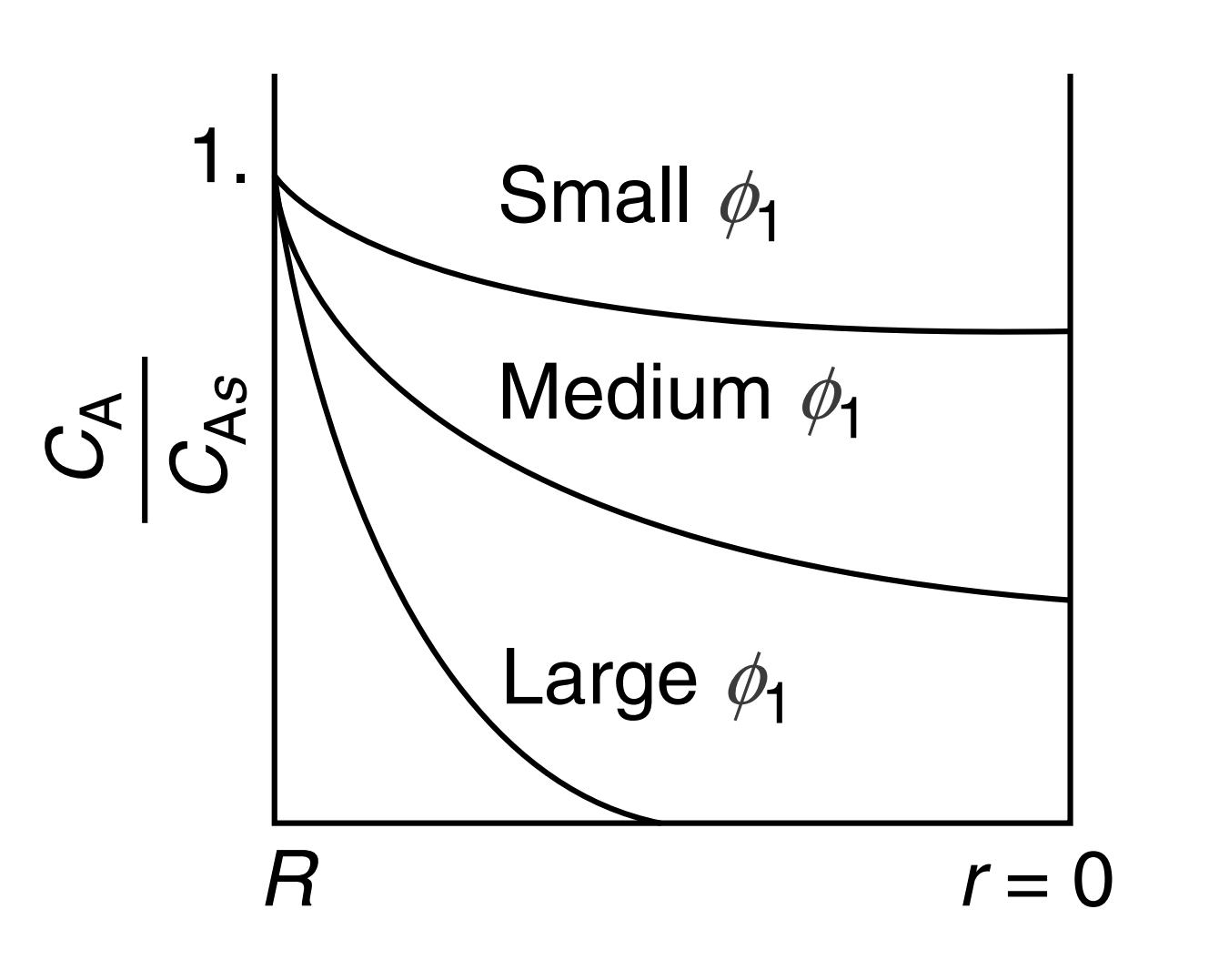

dλ2d2ψ+λ2(dλdψ)−ϕ2ψn=0

- Thiele modulus

ϕn2=DeknR2CAsn−1=De(RCAs−0)knRCAsn=“a” diffusion rate“a” surface reaction rate

- When the Thiele modulus is large, internal diffusion usually limits the overall rate of reaction; when ϕn is small, the surface reaction is usually rate-limiting.

Diffusion and reactions in spherical catalyst pellets

- Dimensionless concentration profile

ψ=CAsCA=λ1(sinhϕ1sinhϕ1λ)

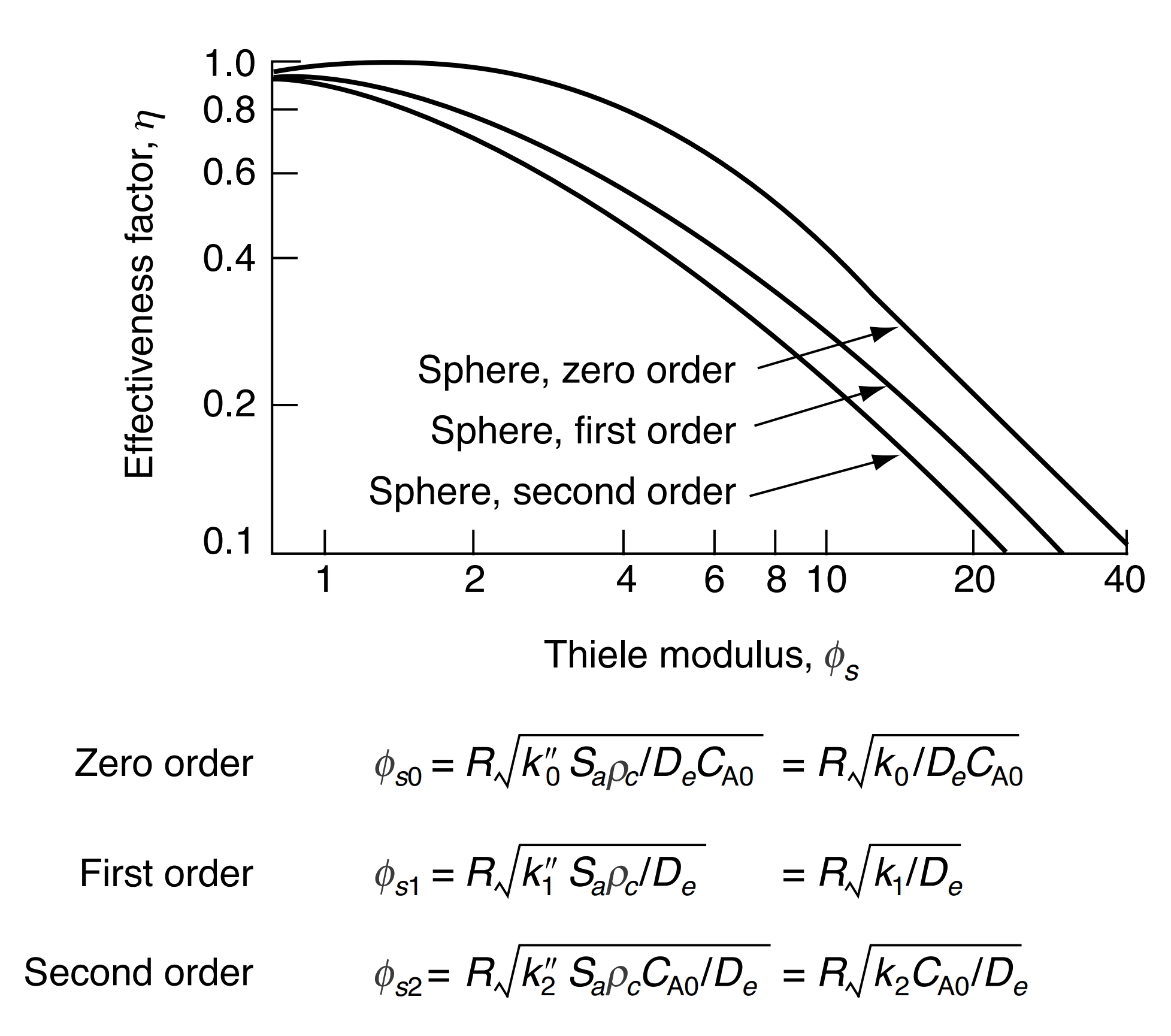

The internal effectiveness factor

- The magnitude of the effectiveness factor (ranging from 0 to 1) indicates the relative importance of diffusion and reaction limitations.

η=Rate of reaction that would result if entireinterior surface were exposed to the externalpellet surface conditions CAs,TsActual overall rate of reaction

- Overall (observed) rate

η=−rAs−rA=−rAs′−rA′=−rAs′′−rA′′

- Effectiveness factor for first order reaction spherical pellet

η=ϕ123(ϕ1cothϕ1−1)

- Reaction rate −rA=η(k1CAs)

If ϕ1<2: η≈ϕ123[ϕ1−1]

If ϕ1>20: η≈ϕ123

The internal effectiveness factor

The internal effectiveness factor

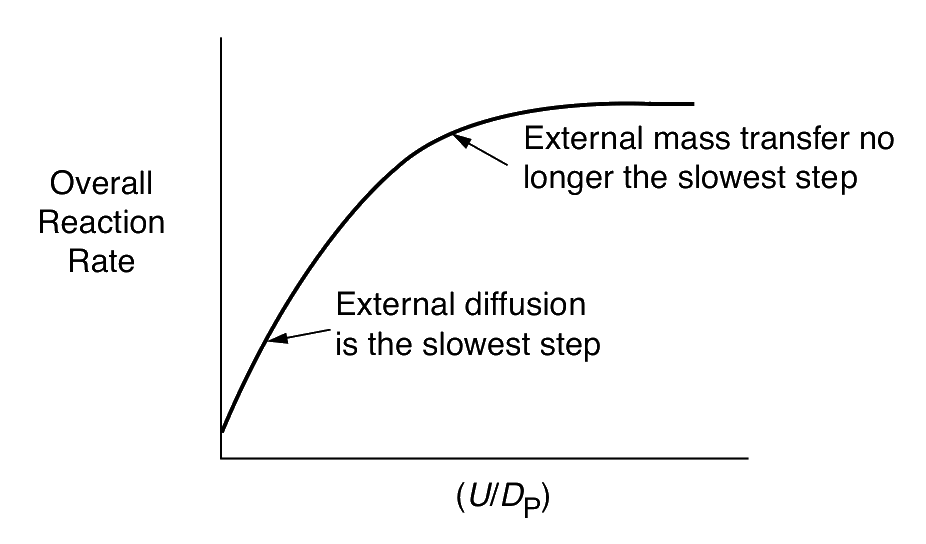

Determination of limiting situations from reaction- rate data

Reaction rate per unit mass of catalyst −rA′=kcacCA

kc∝dp1/2U1/2;ac∝dp1

For external mass transfer–limited reaction

−rA′∝dp3/2U1/2

| Type of Limitation | Velocity | Particle Size | Temperature |

|---|---|---|---|

| External diffusion | U1/2 | (dp)−3/2 | ≈ Linear |

| Internal diffusion | Independent | (dp)−1 | Exponential |

| Surface reaction | Independent | Independent | Exponential |

This component is an instance of the CodeMirror interactive text editor. The editor has been configured so that the Tab key controls the indentation of code. To move focus away from the editor, press the Escape key, and then press the Tab key directly after it. Escape and then Shift-Tab can also be used to move focus backwards.

Chemical Reaction Engineering