Multiple reactions

Chemical Reaction Engineering

Introduction

- Usually, more than one reaction occurs within a chemical reactor

- Minimization of undesired side reactions that occur with the desired reaction contributes to the economic success of a chemical plant

- Goal: determine the reactor conditions and configuration that maximizes product formation

- Reactor design for multiple reactions

- Parallel reactions

- Series reactions

- Independent reactions

- More complex reactions

- Use of selectivity factor to select the proper reactor that minimizes unwanted side reactions

With multiple reactions, either molar flow or number of moles must be used in setting up the balance equations (no conversion!)

Isothermal reactions in PBR: molar flow rates

Second order reaction aA+bBcC+dD

Mole balance: Write balance for each species i=1 to N

dWdFi=ri′

Rate law

−rA′=kCAαCBβ;−arA′=−brB′=crC′=drD′

Stoichiometry Ci=(1+ϵX)CA0(Θi+νiX)(P0P)(TT0)

Pressure: dWdP=−2pα(T0T)FT0FT

Total molar flow rate: FT=∑i=1NFi

Combine:

Collate all equations from steps 1 to 3 to yield a system of equations

Evaluate:

Use ODE solver to solve the system of equations obtained in step 4.

Parallel reactions

Competing reactions

Reactant is consumed by two different pathways to form different products

AkX1DAkX2U

Examples

Ethylene oxidation

CX2HX4+OX2CX2HX4+OX2CX2HX4O2COX2+2HX2Oethylene oxidecomplete combustion

Fischer Tropsch synthesis

CO+3HX2CO+2HX2kX1CHX4+HX2OkX2[CXnHX2n]Xn+HX2O

Series reactions

Consecutive reactions

Reactions where reactant forms an intermediate product, which reacts further to form another product.

AkX1DkX2U

Example

- Ethylene oxide (EO) + Ammonia

CX2HX4O+NHX3(HOCHX2CHX2)NHX2+CX2HX4O(HOCHX2CHX2)X2NH+CX2HX4O(HOCHX2CHX2)NHX2desired product(HOCHX2CHX2)X2NH(HOCHX2CHX2)X3N(mono ethanolamine)(di ethanolamine)(tri ethanolamine)

Independent reactions

Reactions that occur at the same time

Neither the products nor the reactants react with themselves or one another

AkX1DCkX2U

Example: Cracking of crude oil

Hundreds of reactions

CX15HX32CX8HX18CX12HX26+CX3HX6CX6HX14+CX2HX2

Complex reactions

Multiple reactions involving a combination of series, parallel, and/or independent reactions

A+BA+CEkX1C+DkX2EkX3G

Example: Formation of butadiene from ethanol

CX2HX5OHCX2HX5OHCX2HX4+CHX3CHOCX2HX4+HX2OCHX3CHO+HX2CX4HX6+HX2O

Desired and undesired reactions

Parallel reactions AADu←desired product←undesired byproduct

Series reactions Adesired productBU

Minimize formation of U and maximize formation of D

Greater the amount of U ← lower production of desired product, higher cost of separation ← lower profits

Instantaneous selectivity (S)

- Instantaneous selectivity of D with respect to U is the ratio of the rate of formation of D to the rate of formation of U

SD/U=rUrD=rate of formation of Urate of formation of D

- Gives insights in choosing reactors, operating conditions, and reaction schemes that will maximize profit.

- Used to guide initial selection of reactor system.

- Final selection is made after calculating the overall selelctivity for the reactor and operating conditions chosen.

Overall selectivity (Sˉ)

SˉD/U=FUFD=Exit molar flow rate of UExit molar flow rate of D

For CSTR:

FD=rDV

FU=rUV

∴FD/FU=rD/rU=SD/U=SˉD/U

For batch reactor:

SˉD/U=ND/NU

ND,NU: Number of moles of D and U at the end of the reaction.

Yield (Y)

Instantaneous yield (YD)

Ratio of the reaction rate of a given product to the reaction rate of key reactant A

YD=−rArD=Rate of consumption of ARate of formation of D

Overall yield (YˉD)

Ratio of moles of product formed at the end of the reaction to the number of moles of the key reactant A, that have been consumed.

YˉD=For CSTRFA0−FAFD=For batch reactorNA0−NAND

- Overall selectivities (Sˉ) and yields (Yˉ) are important in determining profits

Conversion (X)

Gives insight into problem

Often conflicts with selelctivity

Ideal world ⇒ make as much D as possible simultaneously minimize U

Practical experiece ⇒ Greater the conversion, more the undesired product

Not used in solving multiple reaction problems, but calculated later for analysis

For species A XA=Flow systemFA0FA0−FAXA=Batch systemNA0NA0−NA

For species B XB=Flow systemFB0FB0−FBXB=Batch systemNB0NB0−NB

Derive expression for conversion for a semibatch system where B is fed to A

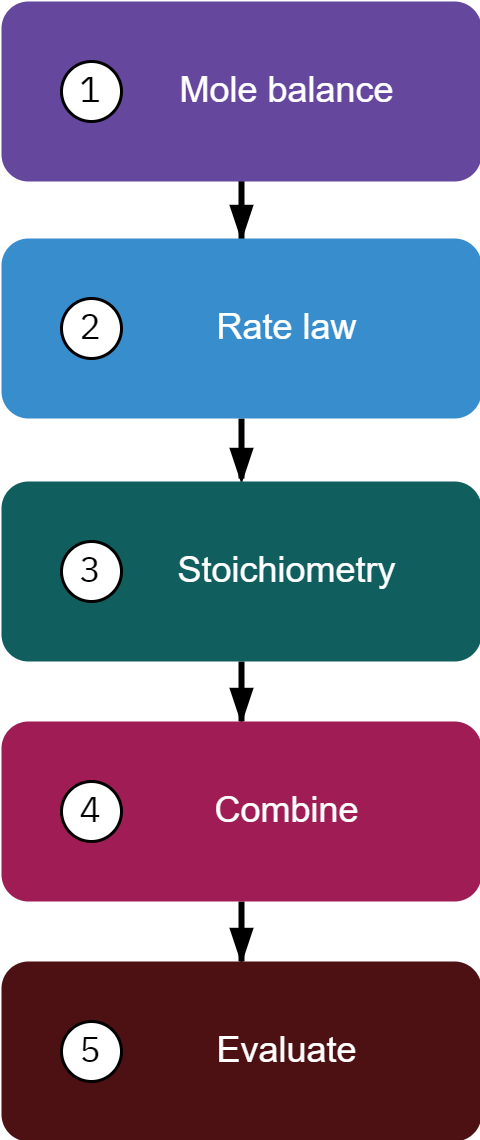

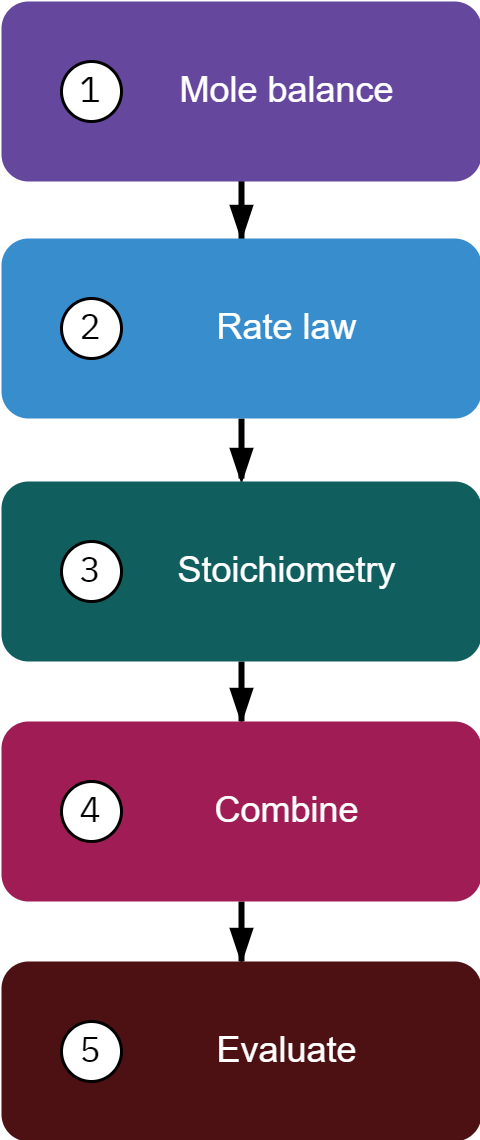

Algorithm for multiple reactions

Number each and every reaction separately.

Mole balance on each and every species.

Fj0−Fj+∫VrjdV=dtdNj

For every reaction write rate law. Calculate the net rate of reaction and relative rates

For component j: rj=∑i=1Nri,j

Stoichiometry

Combine:

Collate all equations from steps 2 to 4 to yield a system of equations

Evaluate:

Use ODE solver to solve the system of equations obtained in step 4.

Can be applied to parallel, series, independent, and complex reactions.

For liquid systems concentration is usually preferred variable for mole balance.

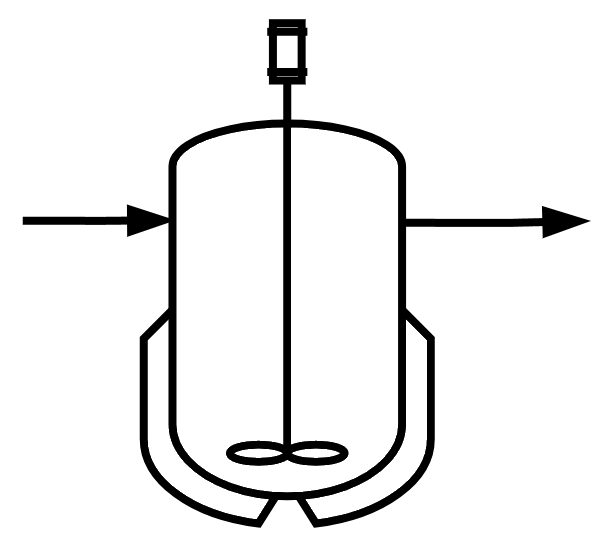

Reactor configurations

Parallel reactions: Selectivity

Consider two competing reactions

ADAU(desired)(undesired)rD=kDCAα1rU=kUCAα2

Net rate of disappearance of A

−rA=rD+rU=kDCAα1+kUCAα2

SD/U=rUrD=kUkDCAα1−α2

α1, α2 are positive orders

Case 1: α1>α2

α1−α2=a

SD/U=kUkDCAa

To maximize selectivity we wan to carry out the reaction in a manner that will keep CA as high as possible during the reaction.

Use PFR or batch reactor

Gas phase: Use high pressure, run without inerts

Liquid phase: minimize diluent

Case 2: α1<α2

α2−α1=b

SD/U=kUkDCAb1

To maximize selectivity we wan to carry out the reaction in a manner that will keep CA as low as possible during the reaction.

Use CSTR or dilute feed stream

Recycle reactor

- Product stream can act as a diluent

Effect of temperature

Need information on activation energy

Sensitivity to temperature for fixed concentrations (CAa is constant)

SD/U≈kUkD=AUADe−[(ED−EU)/RT]

ED>EU

- kD increases more rapidly than kU with increase in temperature

- Perform the reaction at highest possible temperature

ED<EU

kU increases more rapidly than kD with increase in temperature

Reaction should be carried out at lower temperature to maximize SD/U

The temperature should not be very low as it might affect reaction extent. Reaction may not proceed at low temperature.

Two simultaneous reactions and two reactants

Consider two competing parallel reactions

A+BDA+BU(desired)(undesired)rD=kDCAα1CBβ1rU=kUCAα2CBβ2

Net rate of disappearance of A

−rA=rD+rU=kDCAα1CBβ1+kUCAα2CBβ2

Selectivity

SD/U=rUrD=kUkDCAα1−α2CBβ1−β2

- Selectivity depends on the orders α1, α2, β1, β2

- Several reactor combinations exist

Two simultaneous reactions and two reactants

α1−α2=a;β1−β2=b

α1>α2; β1>β2

SD/U∝CAaCBb

Use high CA,CB

Configurations:

- Tubular reactor

- Batch reactor

- High pressure (gas phase)

- Reduce inerts

α1>α2; β1<β2

SD/U∝CBbCAa

Use high CA, low CB

Configurations:

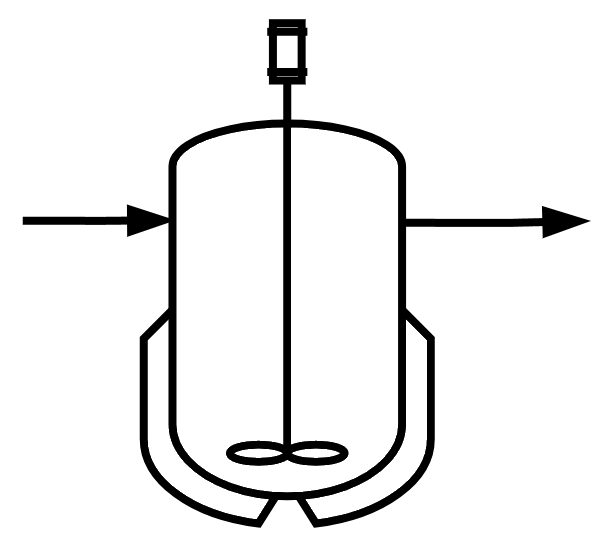

- Semi batch reactor with B fed slowly into large amt of A

- Membrane / tubular reactor with side stream of B continually fed into the reactor

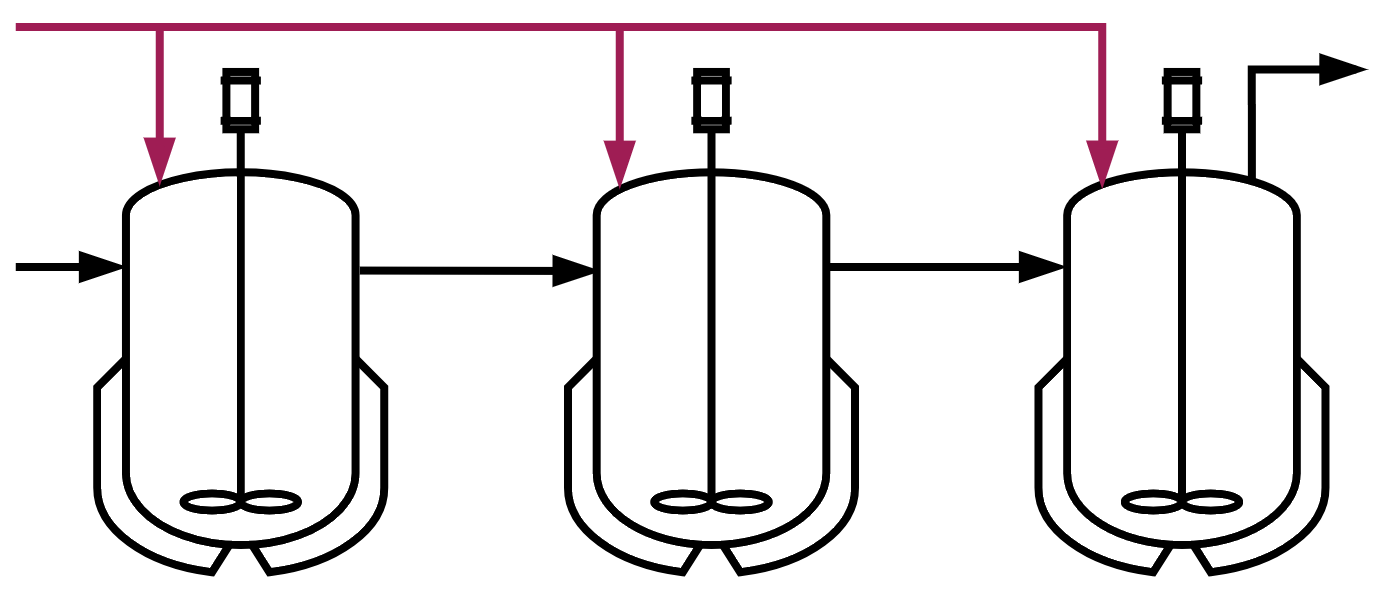

- Series of small CSTRs (A is fed only to the first reactor, B is fed to each reactor)

Two simultaneous reactions and two reactants

α1−α2=a;β1−β2=b

α1<α2; β1>β2

SD/U∝CBbCAa

Use high CB, low CA

Configurations:

- Semi batch reactor with A fed slowly into large amt of B

- Membrane / tubular reactor with side stream of A continually fed into the reactor

- Series of small CSTRs (B is fed only to the first reactor, A is fed to each reactor)

α1<α2; β1<β2

SD/U∝CAaCBb1

Use low CA,CB

Configurations:

CSTR

Feed diluted streams with inerts

Low pressure (gas phase)

Tubular reactor with large recycle ratio

Can be used for highly exothermic reactions. The recycle stream is cooled and returned to the reactor to dilute and cool inlet stream.

Such configuration helps in avoiding hotspots and runaway reactions.

Reactions in series

The most important variable is time

- Batch time (real time)

- Space time (continuous reactor)

Consider: AkX1BkX2C.

B is the desired product

If k1≪k2: First reaction is slow

- Extremely difficult to produce significant amount of B.

If k1≫k2: First reaction is fast

- Large yield of B can be achieved.

If reaction is allowed to proceed for a long time, desired product B will be converted to undesired product C.

Accuracy of prediction for time required to carry out the reaction is vital.

Reactions in series

Consider the reaction

AkX1BkX2C.

B is the desired product, C is waste product.

We are interested in

- Concentration vs. time profile

- Maximum concentration of B

- Quench time (time to stop when CB is maximum)

- Overall selectivity and yield.

Number of reactions

The series reaction can be written as two reactions

AB;−r1A=k1CA.

BC;−r2B=k2CB.

Mole balance dtdNi=riV

For constant volume batch reactor

dtdCA=rA=−k1CA(1)

dtdCB=rB=k1CA−k2CB(2)

dtdCC=rC=k2CC(3)

- Solve Equation 1, Equation 2, and Equation 3 simultaneously to obtain concentration profile.

This component is an instance of the CodeMirror interactive text editor. The editor has been configured so that the Tab key controls the indentation of code. To move focus away from the editor, press the Escape key, and then press the Tab key directly after it. Escape and then Shift-Tab can also be used to move focus backwards.

Chemical Reaction Engineering